Complementary enhancement

The manufacturing dynamics of China and Southeast Asia are such that both sides stand to gain by shifting production bases

By GABRIEL WONG | China Daily Global | Updated: 2020-09-14 08:15

Thanks to the booming opportunities created by the Belt and Road Initiative, the transforming globalization trend, and the changing geopolitical landscape and global economic and trade environment, an increasing number of enterprises, including multinational enterprises with significant presence in China, are reviewing and optimizing their supply chains. These enterprises are evaluating the advantages of relocating and/or expanding their production units from China to Southeast Asian countries with the aim of benefiting from a diversified manufacturing base and expanded market outreach.

Among the Southeast Asian countries, Vietnam, with a population of 96.5 million, is one of the fastest growing economies and poised for robust growth. Although Vietnam is projected to grow only 2.7 percent this year, due to the novel coronavirus pandemic, it is expected to rebound quickly and register GDP growth of 7.5 percent in 2021.

The trend of low value-added manufacturing, notably for consumer electronics, and part of the manufacturing process of multinational companies-particularly those based in Japan and the Republic of Korea such as Sony, Panasonic and Samsung-shifting production from China to Southeast Asian countries has been reinforced by the Sino-US trade frictions. The trade frictions have prompted many companies from China and other countries to remodel and optimize their supply chains to avoid the tariffs the United States administration has threatened to impose on goods made in China.

In fact, foreign direct investment from China to Vietnam in 2019 exceeded $2 billion-double the figure since the US triggered the trade frictions-and is forecast to increase continuously.

However, China still plays a major role in the high value-added and sophisticated product manufacturing, where the production, especially final assembly process requires advanced automation and flexible manufacturing capability, areas in which China enjoys an advantage compared with Southeast Asian countries. This fact is based on our observations and discussions with senior executives of many multinational enterprises.

While leveraging the massive domestic market demand and abundant labor supply, many Chinese manufacturers have managed to operate at a good economy of scale and survive even by making niche products or serving niche markets. Due to the continuous supply of a full range of parts at competitive cost in China, a number of the multinationals are moving only part, not all, of their manufacturing to Southeast Asian countries-just to benefit from the cheaper labor cost and "country of origin" label. They will then ship these semi-finished products back to China for final assembly.

According to the 2020 China Business Survey and Report jointly issued by PricewaterhouseCoopers China and the American Chamber of Commerce in Shanghai in September, of the more than 200 respondents that run or outsource manufacturing operations in China, 70.6 percent said they did not intend to shift production out of China, 14 percent said were moving some of the production process to a non-US location such as a Southeast Asian country, Mexico or India, and only 3.7 percent said they were moving some production to the US.

In the survey, we also asked the senior executives to identify the reasons for reassessing and reducing their investment in 2020.Unsurprisingly, 31.2 percent of them said it was because of the impact of the pandemic, which has exposed the relative complexity and vulnerability of the global supply chains because of lean production.

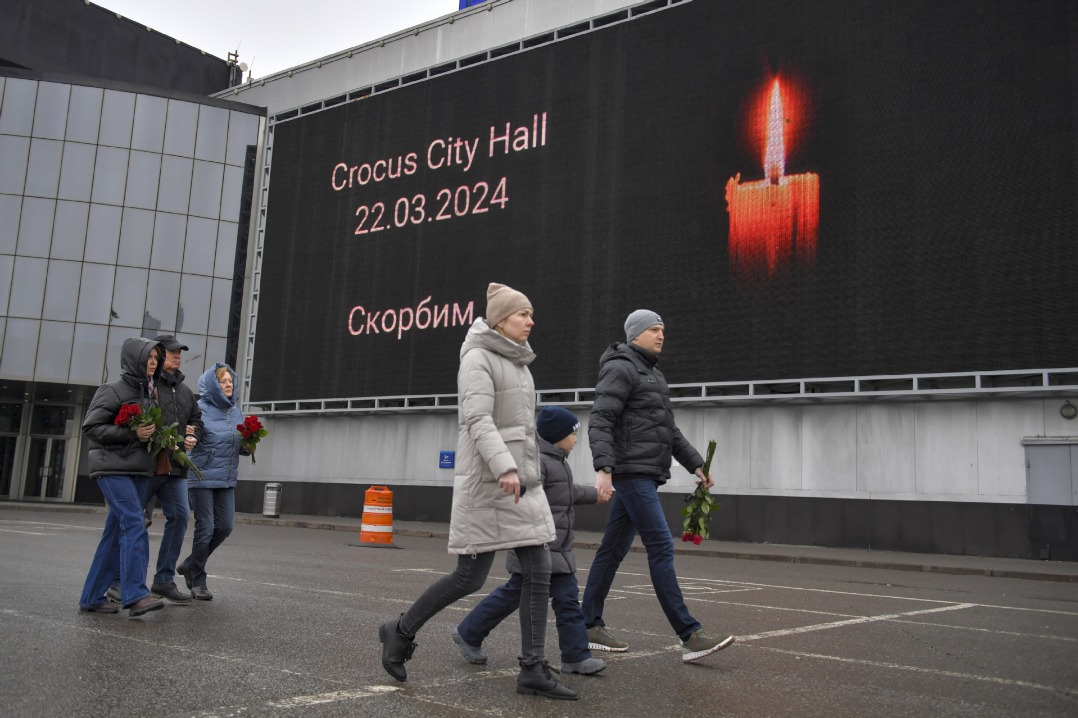

Consequently, the supply chains are being assessed on their agility and flexibility rather than just by cost-effectiveness. Although manufacturing in China was hit by the pandemic in the first half of 2020, the determination and effectiveness of the Chinese government in handling the COVID-19 pandemic-which led to the strong rebound of business activities, in particular, the 10.4 percent export growth in July 2020 compared with the 2.02 percent average growth of other Asian countries-demonstrates the resilience of China's supply chains.

In addition, China's highly developed transportation infrastructure and logistics industry facilitate just-in-time manufacturing and highly efficient production, driving down the total production cost, shortening the time-to-market and enhancing overall customer satisfaction. Also, China's efficient and compact energy and public utility sectors offer a stable and uninterrupted energy supply to the manufacturing units and thus help them to grow. In comparison, the infrastructure and energy sectors in a lot of Southeast Asian countries are relatively less developed and therefore cannot claim overall production efficiency and competitive advantage.

To become a strong player in manufacturing, a country needs to develop heavy industry for machine tools. In China, heavy industry is highly developed and capable of manufacturing different products using machine tools across a wide range of industries. While the industrial development of Southeast Asia has been rapid in the last few years, their production capacity for high-end industrial products remains relatively low, which could slow their pace of catching up with China in industrial development.

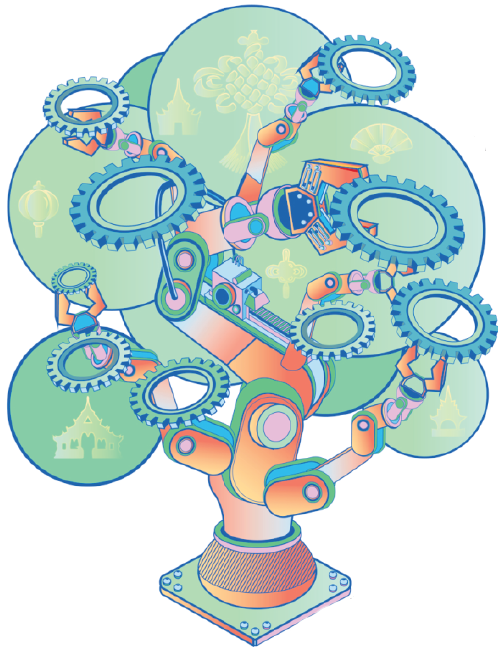

As such, Southeast Asia is unlikely to fully replace China as a global manufacturing hub in the near future. Instead, the region is more likely to supplement China. Relying on its advantages of the economy of scale, industrial and digital infrastructure, heavy industry, and advanced science and R&D, China is developing into a sustainable economy that will transition to a high value-added manufacturing base supported by advanced assembly lines.

However, Southeast Asian countries will get huge economic growth opportunities because of the relocation of part of the manufacturing process from China. The synergy between China and Southeast Asia will help the two sides play complementary roles in producing end deliverables, low-to high-end production, competitive production process of a wide range of products, and benefit from shorter time to market.

Moving forward, China and Southeast Asian economies can come together to form an interconnected "China-Southeast Asia "industrial region and become an expanded "global factory" to collectively increase the importance of Asia in global industrial manufacturing.

The author is head of China Corporate Finance, Inbound/Outbound Leader and Belt and Road Leader at PricewaterhouseCoopers China. The author contributed this article to China Watch, a think tank powered by China Daily. The views do not necessarily reflect those of China Daily.