Firms facing up to tough reality

By Ding Qingfen (China Daily) Updated: 2011-11-23 07:07

|

|

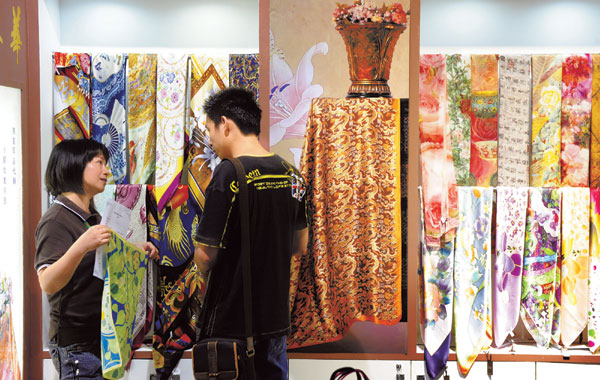

Chinese exporters are finding they must transform their businesses if they wish to survive the turbulent global economy. It doesn't matter whether the products are silk goods (shown at a summer trade fair in Guangzhou), furniture (made in Dongguan, Guangdong province) or something else entirely. Provided to China Daily |

Change is vital in bleak financial times, Ding Qingfen reports in Guangzhou, Guangdong province and Hangzhou, Zhejiang province.

When the global financial crisis hit three years ago, many Chinese exporters crossed their fingers and hoped things would soon get better. Conditions have gotten worse in recent months and the waiting game is over for companies that want to survive.

"Time is pressing. We have to invest more in technology and innovation to make our goods more competitive in the global market," said Zhou Haichang, president of Guangdong-based Guoguang Electric Co Ltd. "This is the only way out, for Guoguang and most exporters."

Business leaders and government officials are driving home the message: Upgrade. Reform. Improve quality. Innovate.

But how? Some companies are shifting markets, adding forward-thinking business lines, revamping their structures or setting up operations overseas.

Such major changes aren't easy, especially for smaller companies, but they are vital. "The way ahead could be paved with thorns, but there is no other choice," one observer said.

Guoguang is China's leading provider of speakers and amplifiers, and its clients include the big names of Bose, Sony and Philips. Business last year in the United States, the European Union and Japan totaled $270 million.

During the first half of this year, sales grew by more than 30 percent from a year earlier - largely because 2010 was so bad - but the second half "should not be pleasing, with sales level with last year at best," Zhou said.

"The worst time since the financial crisis is coming. To be frank, I am very worried about it."

The headwinds

|

|

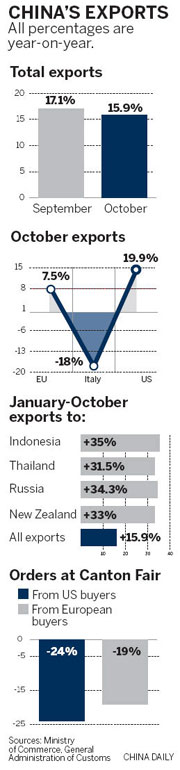

According to the General Administration of Customs, China's exports are still increasing year-on-year, but at the slowest pace since December 2009. At a recent news briefing, Ministry of Commerce spokesman Shen Danyang cited downward pressure from the global slowdown, growing corporate costs and trade protectionist measures, including anti-dumping and anti-subsidy cases.

"China will try to stabilize foreign trade policies to stabilize the growth of exports and encourage exporters to build their own competitiveness by improving technology, brand, quality and services," he said.

The European debt crisis, which started in Greece, is spreading. Mark Carney, new chairman of the Financial Stability Board, the international association of regulators, warned the stresses in the eurozone were creating financial volatility worldwide that would drag down global economic growth.

In the US, the Federal Reserve recently lowered the forecast for its economic growth through 2013. It cited high unemployment and low consumer confidence among the reasons.

In China, currency appreciation and rising costs are squeezing profits for exporters and suffocating some of them. The yuan has gained around 10 percent against the US dollar since China ended a two-year peg to the dollar in June 2010.

The Ministry of Human Resources and Social Security said that, by the end of September, 21 local governments had raised the minimum wage by an average of 21.7 percent, although Chinese labor costs are still comparatively low.

Zhou, from Guoguang Electric, said, "Because of currency appreciation, nobody wants to make and accept long-term orders. I know some small industrial players have died out, as they were incapable of innovation, and many others are very anxious."

But who knows, he said. Maybe the situation has gotten severe enough that more businesses will hear and heed the alarm.

Vulnerable

One of the first things Zhou's company did was boosting its investment in research and development from 3 percent of sales to 5 percent. The R&D team now accounts for 10 percent of employees.

Guoguang is among the electrical and mechanical producers nationwide that have developed a major category of China's exports. Over the first 10 months this year, exports in the category totaled $882.45 billion, 63 percent of the nation's total.

Many of these companies, including Guoguang, are original equipment manufacturers (OEMs), which produce goods or components that are bought by international companies and retailed under their brands.

OEMs are particularly vulnerable in a global recession because many of them are small and have no design or R&D capability, and no sales or distribution network. And with no brand names of their own, they have little leverage in trade.

New sites, products

But even companies with high-reputation brands are stepping up efforts to change and upgrade. Wanxiang Group is the country's largest provider of auto parts and components, with 66.14 billion yuan ($10.4 billion) in sales last year, including overseas sales of $2 billion.

"We are proud to say that Wanxiang is successful. In 2009, our daily profits reached 10 million yuan," said Zhou Jianqun, general manager. "Our target is to grow the figure to 100 million by 2019, but it's not easy, especially when the economic situation home and abroad is grim in the short term."

Still, some earlier ventures are paying off. In 2000, the company made its first foray overseas through acquisition. It now has 28 factories in 14 US states and plans to continue expansion.

It also is reorienting its business growth model to new-energy autos and related goods. Wanxiang Electric Vehicle Co Ltd was set up in 2000 to develop, build and sell electric vehicles and batteries. Cumulative investment has reached 1.2 billion yuan.

In 2009, it started to mass-produce the vehicles. Sales totaled 200 million yuan.

|

|

Lu Hanxin / Xinhua |

Emerging markets

To avoid a slide in orders from developed regions, some Chinese manufacturers and exporters have turned their focus to emerging markets. In the first 10 months this year, for example, exports to Indonesia, Thailand, Russia and New Zealand were up by more than double the average for all exports.

But regional transfers in overseas business don't eliminate the need to innovate and improve products, insiders said.

"As a matter of fact, Brazilian consumers are more and more demanding on the quality of imports," said Andre Saboya Martins, a trade official at the Brazil Embassy in Beijing. "As the Brazilian economy grows rapidly, they want higher quality goods at reasonable prices from China.

"Unfortunately, some made-in-China goods in Brazil are still associated with low quality and low price. This is not good," he said.

Brazil has become an increasingly important market for Chinese exports. They surged 34.5 percent from January to October.

Chinese exporters "need to improve brands, adding value to the goods, investing more on technology and innovation," Martins said. "If they would do these things, Brazilian consumers would think it more worth it to buy. It's good to see they are already under way."

Advantages

|

|

East China's Zhejiang province is the fifth largest region by value of foreign trade and the largest exporter of toys and of light goods such as textiles, shoes and suitcases. It has been urging its companies to upgrade and transform their businesses for three years. As encouragement, the province has provided subsidies or rewards based on company investments in R&D.

Business transformation means "either increasing the value of the products or expanding overseas investment through mergers and acquisitions", said Chen Rufang, who is deputy director-general of commerce for the province. "Transforming to middle- and high-end businesses from low-end could help exporters to maintain competitiveness and reasonable profits while the rising cost is forcing them to raise prices.

"Investment abroad could help them lower operational costs in logistics (shipping) and reduce risks of currency appreciation, creating jobs in the overseas markets."

One business that has transformed itself is Hangzhou Light Industrial Products, Arts & Crafts, Textile Imports and Exports Co. It has changed from a trading company to a supply chain manager in two years. Sales last year totaled $300 million to markets including the EU, US, Japan and countries in the Association of Southeast Asian Nations.

For many years, the company imported raw materials and exported final goods. Now, president Zhang Weimin said, "We have neither factories nor laborers, but we have a fixed number of suppliers doing that. What we did is to diversify and better design, to improve logistics, and to expand the sales network."

The company produces clothes plus bedding, furniture, decorative items for the home - the types of goods shoppers would find at Ikea, Zhang said.

Hangzhou Light Industrial has partnerships in Zhejiang, Jiangsu, Anhui and Fujian provinces with 2,000 suppliers, the majority generating sales worth 5 million to 10 million yuan annually. It develops textile designs itself and receives designs from overseas buyers, then distributes these designs to suppliers to make.

"In difficult times, many of them cannot survive by themselves, but through partnership, they needn't worry about anything as long as we can maintain stable growth in orders," Zhang said.

Cash flow has been a problem for many companies since China's central bank significantly tightened monetary policies last year. So Hangzhou Light Industrial has paid some of its suppliers 50 percent in cash before delivery, alleviating that problem.

Two years ago, it set up a 20-member R&D team, including six from overseas, with cumulative investment exceeding 20 million yuan.

Company business has grown 5 percent annually, Zhang said. "By focusing on R&D and sales, we can maintain such growth, and see little challenge from the global financial crisis."

Distribution system

Eduardas Vaigauskas, general manager of GRG Banking Equipment (HK) Co Ltd, sees a model in much of what Hangzhou Light Industrial has done. He also sees self-imposed limits among many Chinese exporters.

"The bad thing," he said, "is they cannot export (profit) margins, although they are good at manufacturing goods. They are much afraid to go outside, and they are bad at establishing their own distribution systems to keep the profits in hand."

A big proportion of the exporters are OEMs without brand names they can trade on, so they earn tiny profits in their deals, Vaigauskas said. "The majority of the profits go to the international companies. If they (Chinese exporters) would like to grow up, they must do what their international peers do.

"It's not about promotion only, but actively establishing distribution. Otherwise, they cannot succeed."

GRG Banking Equipment is a subsidiary conducting the overseas business of GRG Banking, one of China's largest makers of automatic teller machines. The company began to identify the overseas business as its priority 18 months ago. Now overseas sales contribute 20 percent of GRG's total, Vaigauskas said.

The global recession has challenged the company, but not too much. The company has a well-developed sales network and set up its own distribution system overseas, Vaigauskas said, and it profits from both.

- Seven villagers murdered in N China

- China steps up tobacco control efforts

- Five jailed for separatism in Xinjiang

- Letter asks for leniency in poisoning case

- Antibiotics in surface water pose 'indirect health risk'

- Tianjin airport opens up transit link to Beijing

- High levels of antibiotics in China's major rivers

- China to dig tunnel for Asian rail system

- Bering strait line to US possible, experts say

- China: Stop oil rig harassment