Using a printer to produce lifesaving medical implants and body parts might sound like science fiction, but it is already a reality in China.

Peking University Third Hospital, a top hospital in China, recently announced that its Orthopedics Department has been using enhanced implants produced by a 3-D printer in a clinical trial, with promising results.

|

|

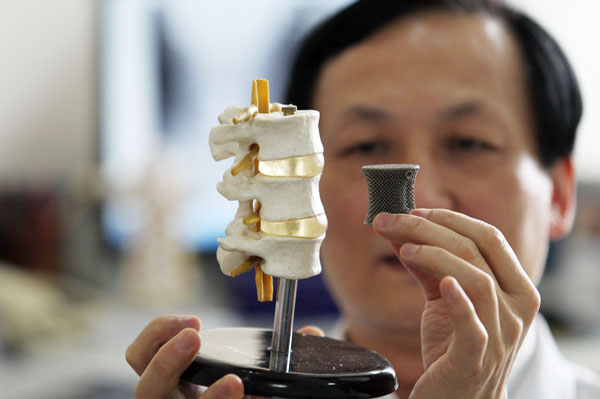

A 3-D printed medical implant is shown at Peking University Third Hospital in Beijing, Aug 6, 2013. Dozens of such implants have been used in more than 50 patients, said Liu Zhongjun, director of the Orthopedic Department of the hospital. [Photo by Zhu Xingxin/Asianewsphoto] |

"We started clinical trials on 3-D produced implants late last year, and now we have used dozens of such implants in more than 50 patients," said Liu Zhongjun, director with the department.

"All the patients recover very well. Nobody seems to have any undesirable side effects or adverse reaction."

The process of 3-D printing, or additive printing, applies successive layers of material in different shapes to make a three-dimensional solid object from a digital model.

For the implants, the material used is titanium, a special metal that has been used for orthopedic implants for decades.

However, the shapes of the 3-D products are much different than earlier models.

Orthopedic implants are artificial devices incorporated into joints and bones to restore normal functions, such as spine implants to help anchor the spine, or hip replacements.

They are widely used for patients suffering from bone damage caused by injury or disease, such as osteoarthritis, which causes pain and stiffness in joints.