Surviving economic changes in industry

By Gao Changxin in Wenzhou (China Daily) Updated: 2012-04-09 11:07

|

|

|

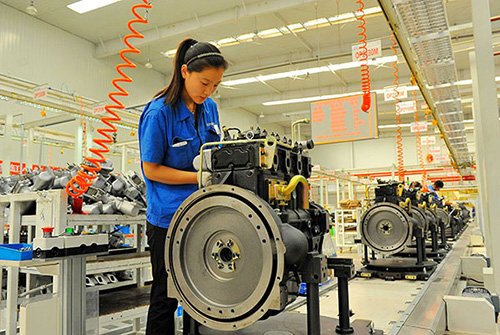

A private shoemaking company in Wenzhou, Zhejiang province. The private economy hub is adopting new technologies to help its manufacturers maintain their competitive edge. [Photo/China Daily] |

Wily shoemakers improved company productivity by modernizing plant

In a factory in the city of Wenzhou, Zhejiang province, Luo Li, vice-general manager of shoemaker China Juyi Group, talked proudly about how new laser machines have helped to improve its productivity.

Before, she said, it took a skilled worker an hour to make hollow patterns on a shoe's leather upper wrap. But with the laser machine, everything is done in two seconds.

"Few shoemakers worldwide have the technology. It boosts our efficiency exponentially," she said.

Wearing a pair of protective glasses, a worker set a piece of leather on a panel, pressed a button, and a complicated pattern appeared almost instantly on the leather, which will be used to make ladies' sandals for export to Europe.

The laser machines are just one of the many technological improvements Juyi, a leading shoemaker in the city, has made in recent years.

By constantly improving its technology, Juyi managed to grow from a 20-strong workshop to a modern manufacturing base with 5,000 employees and annual exports of more than $100 million.

While many other local shoemakers have collapsed, Juyi has become bigger and stronger.

|

|

|

An international shoe exhibition in Jinjiang city, Fujian province. The upgrading of the country's manufacturers is an example of the transition to a more technology-driven growth pattern. [Photo/ For China Daily] |

The development of Juyi and that of the shoe industry in Wenzhou, the hub of China's private economy, stands as an example of the nation's rise over the past 30 years as a world factory and the ongoing process of industrial upgrading, said industry analysts.

Thirty years ago, thousands of small-scale shoemakers in Wenzhou set an example for the country on how to earn export dollars.

Three decades later, Wenzhou's shoemakers are once again setting the pace for the country's manufacturers on how to remain competitive as their initial advantages - low labor costs, a favorable foreign exchange rate and ample resources - fade away.

By improving manufacturing technology and developing its design capabilities, Juyi has been able to double its sales over the past five years without adding to its payroll.

Juyi's exports grew more than 20 percent in 2009, while many other companies' exports tumbled in the aftermath of the global financial crisis.

Around 10 km away, Wenzhou Kangnai Group Co Ltd is making plans to build itself into an international shoe brand after having acquired more than 30 patents since it was founded in 1980.

The export price of its shoes now averages $25 a pair, more than double the industry average in China, the company said.

By making shoes that his competitors are unable to manufacture, it also weathered the financial crisis with double-digit growth.

Kangnai plans to open 1,000 direct-sales stores over the next five years as part of a plan to bypass downstream distributors and achieve higher margins.

Kangnai and Juyi are in the vanguard of an ongoing shoe industry transformation in Wenzhou that started about a decade ago, which has resulted in higher manufacturing efficiency, said Wang Ying, secretary-general of the shoe industry branch of the China Chamber of Commerce for Import and Export of Light Industrial Products and Arts-Crafts.

During the process, the number of shoemakers in Wenzhou plummeted from more than 6,000 a decade ago to a little over 1,000 today. But the industry's export volume tripled to $4.7 billion in 2011 from just $170 million in 1999.

"The shoe industry here in Wenzhou has significantly consolidated over the past decade. Many who refused to make changes died while others who adapted themselves to the market through innovation have survived, resulting in the industry becoming stronger," said Xia Linhong, a senior official with Wenzhou Bureau of Commerce.

"This is a trend that will continue and may finally create some big international shoemakers."

The transformation of Wenzhou's shoe industry is what Beijing has been advocating in recent years, and comes amid growing realization that the labor and resource-intensive growth pattern that drove China's miraculous economic development over the past 30 years is no longer sustainable.

Labor costs, for one thing, have shot up significantly over the past few years, pushing up manufacturing costs.

The Ministry of Human Resources and Social Security said that the minimum wage increased by an average of 21.7 percent year-on-year in 21 provinces last year.

Raw material prices are also surging, as is the yuan's exchange rate against the US dollar.

The combination of these factors drove many of the country's low-end manufacturers to the brink of bankruptcy because their business model gives them a thin profit margin and little bargaining power over export prices.

In fact, industry restructuring and upgrading is one of the country's top economic priorities during the 12th Five-Year Plan (2011-2015).

President Hu Jintao and Premier Wen Jiabao have repeatedly urged the country's exporters to sharpen their competitive edge through transformation and upgrading.

In fact, many shoemakers in Wenzhou embarked on upgrading before their businesses faced any problems.

"What's great about entrepreneurs in Wenzhou is that they are always prepared for problems and are willing to take risks. They have this entrepreneurial spirit," said Lu Huamao, head of the foreign trade department of Wenzhou Bureau of Commerce.

Zhou Jinmiao, vice-general manager of Kangnai, said that his company realized that there was no future in just being an original equipment manufacturer.

"You will always be an underdog doing just OEM, no matter how big you are. You do what others tell you and have little say over prices," said Zhou.

"So we took preemptive steps to add more value to the business we do."

One of the steps Kangnai took was to build its own sales channels.

Among its overseas outlets, some are high-end stores, through which Kangnai expects to enhance its brand image.

Kangnai has also entered into a partnership with the British-based SATRA Technology Center, which provides the footwear industry with services in technical knowledge, research and testing.

These efforts, said Zhou, require a handsome investment, but offer no short-term returns.

"Most manufacturers in China know what to do to upgrade their business, but few have the guts to do it because it's risky and you can't see the returns in the short term. We did it and it has started paying off," he said.

Gold Emperor Shoes Co Ltd, another Wenzhou shoemaker, adopted a different method, vowing to become the "Foxconn of China's shoe industry".

Zhu Jianfeng, Gold Emperor's general manager, said his company would not go downstream into retail but will focus on manufacturing and expand in scale.

"Building brands is not the only way to upgrade. We want our name to come up first if any foreign clients want to outsource their shoe manufacturing to China," said Zhu.

Gold Emperor is Zhejiang province's biggest shoe exporter, with its export volume hitting $146 million in 2011. Starting in a small workshop in 1993, it now owns a 49,000-square-meter factory with 21 production lines and around 4,500 employees.

By ensuring top-notch product quality and sharing design work with its clients, Gold Emperor, which currently only exports to Europe, continued to grow despite the global financial crisis and is now exploring ways to enter the domestic market.

"We have invested massively in new technology over the years and it has paid off handsomely for us," said Zhu.

"What shoemakers have done in Wenzhou has been very impressive. We are working on spreading their experience to shoemakers elsewhere and to other industries," said Wang Ying, secretary-general of the CCCLA.

There are also pitfalls on the entrepreneurs' road to upgrading and transforming their business.

Most of the country's successful manufacturers have entered China's booming real estate market, said Wang.

China's real estate boom over the past decade provided private capital with the chance of realizing lucrative investment returns.

As a result, many entrepreneurs strayed from manufacturing, which has lower margins, and poured their capital into the property market in pursuit of high margins.

But as the government has tightened its grip on credit and cracked down on property prices, many have been driven to the verge of bankruptcy and are borrowing from underground lenders.

"I am glad that I resisted the temptation of the property market. If I had dived into that market, my company wouldn't be as strong and healthy as it is today," said Qiu Zhiming, president of Beifa Group Co Ltd, a pen-maker based in Ningbo, Zhejiang province. Beifa sells 2 billion pens annually to 150 countries.

Qiu described the property market as a "drug" for entrepreneurs, which produces temporary pleasure but long-lasting pain.

Many of Qiu's friends invested in the property market and made some easy money, but they left manufacturing behind and are now facing severe problems.

Qiu said he could have easily raked in 100 to 200 million yuan from the property market, but he didn't do that because he knows what he is good at and which businesses are sustainable and which are not.

Many companies wanted to maintain their business scale and only invested retained earnings in the property market.

But Lou Fuan, general manager of Deli Group Co Ltd, a stationery maker based in Ningbo, Zhejiang province, said that it is impossible to "maintain scale".

"You either get bigger or get smaller, it's the rule of the market. I know that so I stuck to what I do," said Lou, whose company has 2.1 billion yuan in assets and around 2 billion yuan in annual sales.

Chinese manufacturers are in a pivotal period, said Luo, when many will die and some will come out much stronger. "And the way to survive is to stick to what you are good at and do it really well," he added.

gaochangxin@chinadaily.com.cn

- Chinese stocks down on Brexit fears

- Hong Kong's stocks extend gains to fifth day

- Foreign takeovers in Germany are 'positive'

- BOC's international SME matchmaking on the rise

- Warren Buffett invests in Oklahoma State kin, Tyler Buffett

- People business that goes beyond numbers

- Experts mull impact of UK referendum

- Investors welcome tests next week for Shenzhen-HK trading link