Sitting pretty in a car

By Wang Chao (China Daily) Updated: 2012-11-03 15:05Doors and windows of opportunity open for auto systems manufacturers

China may no longer be virgin territory for Western car companies, but there are still niche markets to explore, such as those for door and seat systems, window regulators and electric drives.

On Oct 18, German automotive supplier Brose Group opened its seventh Chinese factory in Beijing. The company began producing door systems in the 14,000-square-meter plant in early 2011, for the C-Class, E-Class and GLK models made by Beijing Benz Automotive Co.

|

|

|

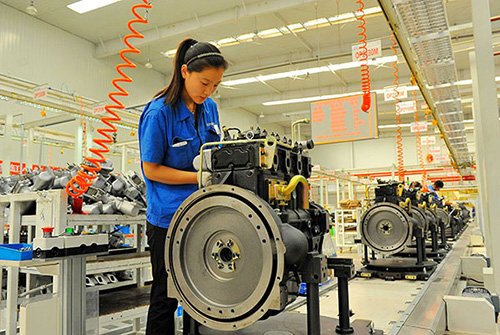

Brose Group's employees work at its new plant in Beijing. The German automotive supplier of window regulators, door and seat systems, and electric drives sees niche markets in China. [Provided to China Daily] |

Established in 1908, Brose makes window regulators and door systems, proudly claiming that one in three vehicles in the world is assembled with its products.

The Chinese market was the highlight of Brose's performance in 2011. It has been growing by 25 percent annually for the past few years, while the average growth rate in other regions is about 10 percent.

Brose entered the Chinese market in 1995, and currently has seven sites in five cities. It has localized its entire product portfolio and established a research and development team in China.

Last year the company invested 720 million yuan ($115 million; 89 million euros) to expand its Chinese facilities and a new plant in Chongqing was opened in July, serving automobile companies in Southwest China.

Shanghai is its Asian headquarters, and also serves the South Korean and Thai markets.

Thomas Spangler has been working for Brose for 20 years. As Asia president, he says China and North America are its two fastest growing markets.

"Looking back 20 years, the company had only 350 million euros sales. Today we have 4.4 billion euros," Spangler says.

The company now employs more than 3,500 people in China and expects to generate revenue of 6.5 billion yuan in 2012.

"Brose started the business of door systems with BBAC (Beijing Benz Automative Co) this year, and due to the volume upgrade of BBAC, we will have additional door system lines coming next year," Spangler says.

Other product lines for BBAC will be introduced in 2013, he adds.

Brose is also preparing to relocate some cooling fan lines from Wuhan to Beijing, as it is closer to its major client Great Wall Motor Co.

Angel Legerda, general manager of BBAC procurement and supplier management, says it is important to have major suppliers around, as Mercedes-Benz is planning to expand production capacity to 300,000 by 2015 from 100,000.

"We're thankful for Brose being here, so we can improve our supply chain and achieve better localization," Legerda says.

Workers have around five hours to assemble, inspect and ship a ready-to-install door system after receiving an order from its client, the BBAC factory 8 kilometers away, says Harley Yu, general manager of the new Beijing plant.

This plant will be the second in Asia using the just-in-sequence (JIS) method to produce and ship door systems in pace with vehicle production.

"We launched JIS production of door systems at our Shanghai plant in May 2000, BBAC's first supplier to do so in China," Yu says.

Brose operates 13 JIS production plants worldwide. The Beijing factory will also begin producing window regulators for local car makers Beijing Automotive Industry Holding Co before the end of this year.

William Tang, president of Brose China, says the fastest growing section of Brose is the seat system.

"The scale of the seat system has grown from zero to 25 to 30 percent of the Chinese market (in the past five years)," he says.

As the requirements on materials are stringent, only 50 percent of the window systems are made locally, with the rest imported. Other product lines have found more local resources. The localization rate of door systems is 85 percent.

This year, the company has sensed another business opportunity. The Chinese government issued a policy that from Jan 1 this year cars with electronically controlled windows should be fitted with anti-pinch devices.

Brose was among the first producers of the anti-pinch window regulator, which retracts the glass when sensors detect anything stuck between it and the frame - such as children's hands and necks.

The safety device has been widely adopted by major auto suppliers and every year, about 7.5 million anti-pinch electronic modules are sold in China, 25 percent of Brose's global supply.

The market still has room for growth. Although 80 percent of cars in China are equipped with electronically controlled windows, many are not anti-pinch.

In the past two years, the Chinese auto market has cooled down, and most auto suppliers, including Brose, have felt the chill and adjusted their revenue expectations.

Nevertheless, Tang still projects a double-digit growth rate for Brose in the next three to four years, adding that by 2015 the company will earn revenue of 10 billion yuan in China.

"The average ownership of cars in China is still low, so the potential is huge," he says.

But the increasing labor costs in China is an issue Brose cannot circumvent.

"The rising labor cost is an issue every company in China has to deal with, including our competitors," says Spangler. "But it does not affect as much because we also produce for other markets.

"The measure we are taking at the moment is looking for higher degrees of automation in the assembly lines, and in further training of our people."

Whatever happens, Brose will not turn away from the Chinese market.

"The Chinese market is really important and too big for that," Spangler says. "The other markets we expect to raise are in the Southeast Asian region - Thailand and Malaysia - but this will still take a long time and can never replace the Chinese market."

wangchao@chinadaily.com.cn

- Mushroom cultivation bases established in Ningxia

- ZTE to launch VR-related mobile product, says its executive

- China's forex reserves rise to $3.22 trillion

- Central bank pledges to keep prudent monetary policy

- Chinese oil firms' assets affected by wildfire in Canada

- Shanghai Disneyland starts soft opening on Saturday

- IMF: Economic restructuring 'desirable'

- Expo shines light on next generation of jewelry pieces