3D printing, China's new growth point

(Xinhua) Updated: 2012-12-18 09:25WUHAN - China plans to invest in locally-invented 3D printing technologies to boost its manufacturing power, according to a senior industrial official.

Su Bo, Vice-Minister of Industry and Information Technology, said the country should establish plans and use tax incentives to speed up research and development (R&D) and application of 3D printing technologies.

|

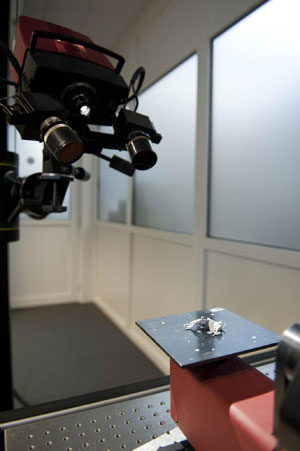

Cutting, bending, pressing, moulding and assembling will no longer be necessary in the manufacturing as a click of the printing button on a 3D printer will automatically produce a solid product based on the pre-set three dimensional data.

"It is a revolutionary manufacturing technique. Once put to large-scale production, it will ease China's pressure on energy and resources," said Su at an international forum on additional manufacturing technology, which closed in Wuhan on Sunday.

David Bourell, a professor of the University of Texas at Austin, in the United States, sees great potential in the application of additional manufacturing in China.

Even if the smallest portion of consumer goods are produced through 3D printing, the market volume will be tremendous, he said.

China is the world's biggest manufacturer. If the technology can be put to broader use, the country's productivity and energy- and resource-use efficiency will improve greatly, said Su Bo.

President Li Peigen with the Huazhong University of Science and Technology said that China was almost on par with developed countries in R&D and application of the leading technology.

The university's Fast Manufacturing Center has invented a 3D printer which can produce the world's biggest product through additive manufacturing technologies.

|

Academician Lu Bingheng with the Xi'an Jiaotong University took the development of 3D printing equipment as an "indicator of the dynamic and innovation capability of an economy."

China has only 8.6 percent of the world's total 3D printers compared to 38.5 percent for the US, he noted.

"Additional manufacturing technique will enable manufacturers to shorten production cycle, better meet individual needs and easily cope with the production of complex or large-scale components. There is much to be done for domestic researchers," he said.

Since Chinese researchers ventured into the sphere in late 1990s, a series of home-invented additional manufacturing techniques have been applied to bio-additive manufacturing, ceramic forming and laser sintering.

At the three-day forum, domestic manufactures showcased their latest products from chic mobile phone shells, fancy attire, lamps, shoe-pads to complex industrial components.

China's leading researching institutes in this area include the Xi'an Jiaotong University, Huazhong University of Science and Technology, Tsinghua University and Beijing Long Yuan-Automated Fabrication System.

First invented by American scientists in 1990, 3D printing technologies have been used in aerospace, medical care, construction, sports, entertainment and automobile industries overseas, according to Graham Peter Tromans, chairman of the Additive Manufacturing Association of the United Kingdom.

- Tax innovative industries to ensure fairness: Lou

- G20 should support a new tax system for growth: China finance minister

- China's steady economic development helpful to the world: Australian economist

- Global cooperation needed on fiscal policies: China's finance minister

- G20 Finance Ministers and Central Bank Governors Meeting kicks off in Chengdu

- PBOC urges better financial support to flood-hit areas

- WTO concludes China's sixth trade policy?review?

- Regulators warn Vanke, Baoneng