Free trade agreements that will transform China Inc

By Zhong Nan (China Daily) Updated: 2016-01-18 07:48

|

|

Models and an LG group executive display the South Korean company's latest products. [Photo/China Daily] |

Experts said China's fast-growing 4G telecom networks and the "Made in China 2025" development plan will lead to improvement in productivity and resource efficiency. Their potential benefits are even greater if they are extended to all stages of the value chain-suppliers, manufacturers, and customers, as well as global markets.

Between 2010 and 2050, China's workforce as a share of the population will probably shrink from 72 percent to 61 percent. So, inter-connected industrial operations will require a different kind of workforce and skill-sets in manufacturing. Demand for engineering and IT skills will likely increase, according to an October 2015 research paper of the Beijing-based Institute of Industrial Economics, which operates under the aegis of the Chinese Academy of Social Sciences.

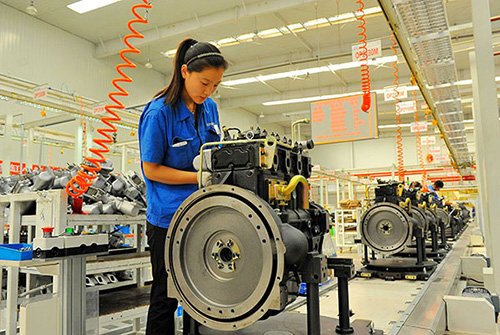

Zhi Luxun, deputy director-general of the department of foreign trade at the Ministry of Commerce, said market competition will put pressure on less qualified employees in Chinese enterprises, and Chinese units of South Korean and Australian companies may have to find new opportunities in other sectors such as services and agriculture.

"These shifts will lead to new business models, which will partly substitute old ones. In this context, the two FTAs will bring about a profound transformation in the country, and present a major challenge," said Zhi. "Higher productivity will allow higher wages and may help alleviate labor shortages."

Rather than wait for the market call to get ready for battle, large-scale Chinese manufacturers such as Yantai-based CIMC Raffles Offshore Ltd have already taken the plunge by exporting more offshore oil rigs and engineering vessels to compete with South Korean shipbuilders.

CIMC Raffles completed development of a $550-million deepwater semi-submersible drilling rig named North Dragon at its Yantai production base in East China's Shandong province last month.

The rig was built by CIMC Raffles for North Sea Rigs Holding AS of Norway, one of the largest offshore oil producers in Europe. It is the first China-made semi-submersible drilling rig capable of operating in the Arctic area with temperatures of minus 20 degrees Celsius.

The platform will be able to operate in seawater depths of up to 1,200 meters and drill to a depth of 8,000 meters. Capable of withstanding sea storms, it can work in the North Sea and Barents Sea

Yu Ya, president of CIMC Raffles, said South Korea is capable of producing icebreakers, oil rigs and other specialized vessels, and China's prowess will not immediately impact South Korean shipbuilders. Yet, Chinese companies must diversify to broaden their manufacturing expertise and ensure their global market share is not taken by South Korean companies, he said.

"Major Chinese shipyards and heavy industry manufacturers today are keen to acquire European and US maritime design and research firms in different sizes, because this is a big part of their tactics for gaining high-end technologies to produce core components and compete with rivals in both home and overseas markets," said Yu.

Shipyards in China received orders for new vessels with a collective capacity of 23.58 dead weight tons between January and November in 2015, accounting for 28.7 percent of the global market share. South Korea's shipbuilding industry, a powerful rival of China's, held 38.8 percent of the global market share during the same period.

- Australia to coast on the milky way to export boom

- E-shoppers to get more access to the world

- Chinese crowdfunding on rise amid start-up boom

- Concept cars unveiled at Detroit Auto Show

- Policies help NEV 2015 output to quadruple to 379,000 units

- Chinese luxury shoppers increasingly turning online: KPMG

- As VC firms turn prudent, shakeout hurts O2O startups

- All eyes on key economic data of 2015