Laser-sharp focus on tech transforms manufacturing hub

By QIU QUANLIN (laser) Updated: 2016-05-12 08:23The success of Shenzhen-based Han's Laser Technology Industry Group started when it began providing solutions to thousands of Chinese button makers. Using lasers, it would print logos and labels on their buttons in the late 1990s.

"At the time, Chinese traditional button makers, most of whom were based in the Pearl River and Yangtze River deltas, found it hard to print logos on their output. Yet, they somehow managed to ship their low-end output overseas," said Gao Yunfeng, president of Han's Laser, which was founded in 1996.

The company developed a machine based on laser marking technology. A button maker in Zhejiang province bought the machine.

"Button makers though still hesitated to use our products. But they later realized that marking buttons with brand names boosted the product's image, helped increase its price, and production efficiency too got enhanced dramatically," said Gao.

Machines made by Han's Laser have since been used for a variety of purposes, from imprinting brand logos on buttons to cutting cloth according to patterns to printing the image of the partly eaten fruit on Apple Inc's gadgets. Now, more than 20 industrial sectors use the machines, according to Gao.

The company's sales topped 5.58 billion yuan ($858.7 million) in 2015, taking up to 72 percent share of the domestic laser industry, according to the company.

Its sales increased 18 percent year-on-year to 1.18 billion in the first quarter of 2016, making it one of the top two laser companies in the world.

After becoming the domestic market leader, Han's Laser began expanding into international markets in 2001.

"We have always given priority to technology research and innovation. More than half of the domestic laser technicians are working in our company," said Gao.

Han's Laser has so far developed more than 10 direct international sales offices, with overseas revenue expecting to make up about 20 percent of its total sales this year, according to a company source.

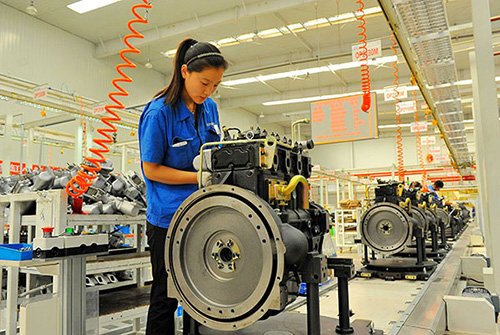

Introduction of smart equipment like the laser marking and cutting machines has helped greatly enhance production efficiency and reduce costs for traditional manufacturers, said Gao.

For example, a laser machine in a smartphone label-marking line would help reduce the need for almost 50 conventional processing workers, according to Gao.

"Advanced technologies and equipment would help upgrade businesses for traditional manufacturers and optimize the local industrial structure," said Gao.

Xu Qin, mayor of Shenzhen, said manufacturers would encourage use of advanced technologies in the years ahead as the city has been intent on optimizing its industrial structure.

More than 17,000 low-end enterprises with intensive manufacturing were closed in the past five years in Shenzhen, which has grown from a manufacturing hub of intensive processing since the 1980s to a powerhouse of innovation and technology, according to the local government.

"Developing emerging future industries does not mean traditional manufacturing will be abandoned. Instead, manufacturers will be given more support to upgrade their business by introducing advanced technologies," Xu said.

According to Xu, the local government will increase investment in the development of precision technologies and advanced manufacturing. It will also strive to introduce more foreign investors in the sector.

"We are making efforts to increase the market value of local manufacturing with precision technologies and other advanced technologies," Xu said.

- Holiday Inn's new model aims to boost growth

- Second child? Malls already ramping up offerings for summer

- Alibaba steps up fight on counterfeit luxury goods

- Shadow looms on overseas-listed Chinese companies' return plans

- How Shenzhen helps Royole shine at the global level

- Stocks hit by reported CSRC ban on non-core buys

- Consumer goods boost on the way

- Top 10 most authentic brands in the world