|

BIZCHINA> Top Biz News

|

|

Jinjiang puts its best foot forward

By Diao Ying (China Daily)

Updated: 2009-01-21 08:01  People may not have heard of a place called Chendai, but they at least know something about the Hong Kong pop singer Jolin Tsai, the world's No 1 tennis player Jelena Jankovic, the NBA basketball star Shane Battier.

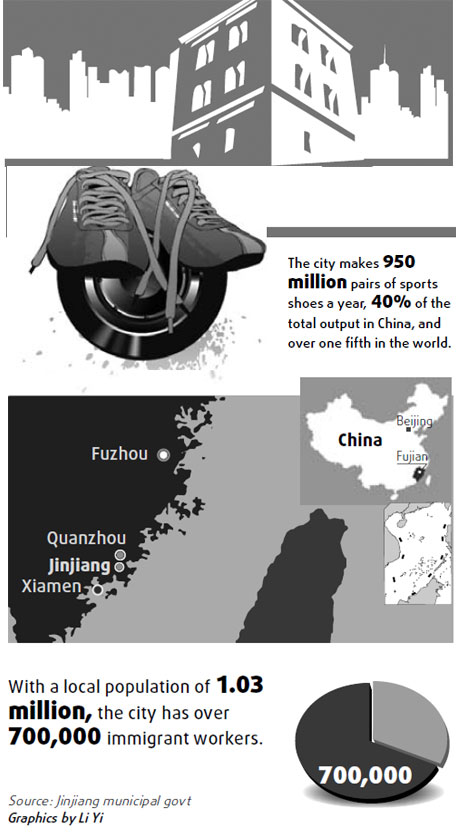

The celebrity list can go much longer, and they all endorse sneakers from Chendai, the obscure small town that's a three-hour drive from Fuzhou, capital of the southeastern Fujian province.

With so many famous and not so famous brands squeezed in such a small place, competition among local enterprises has been fierce for a long time. The market leaders want to stay on top and keep expanding, while smaller companies, want to grow bigger and have their own brand. As the global economic tsunami advanced, these companies found they have much to learn about themselves, as well as their competitors. They found it is easier to survive if the brand of a company is well known to the public, and for those who are yet to establish one, life could be easier if they work together with those who have established their businesses. Xu Gang, the Party secretary of Quanzhou, a city in the Jinjiang area, said having a brand is everything for an enterprise, and this is especially true during hard times. "It is like enterprises with a good brand are in heaven, and those without are in hell," said Xu. Local businesses had long relied on working as original equipment manufacturers, or OEM, for international sportswear companies like Reebok and Puma. Things went well until they suffered a severe drawback in 1998, when the Southeast Asian economic crisis spread. "That year, the GDP of Quanzhou stayed the same as 1997. That means we did not develop at all, we fell behind," said Xu. But 1998 was also a turning point for the local industry. Many OEMs started to realize how vulnerable it was simply to rely on making products for others, and they started to create brands themselves. In 1999, Anta invited Kong Linghui, the world table tennis champion, to endorse it in advertisements. With a bold marketing campaign and heavy spending, the brand soon became famous nationwide. Later, other companies copied the similar model, combining prime time TV ads with celebrity endorsements, and many of them became nationally famous brands. They continue to do so even as the crisis spreads. In the China's Central Television's auction for advertisement of prime time slots for 2009, many shoe companies from Jinjiang have also spent money heavily. 361 became the sole sportswear supplier of CCTV sports channel with 158 million yuan, and X Step bid for sole partnership for the live broadcasting of sports events on CCTV with 156 million yuan. In addition to more effort in brand building, local industry insiders say the crisis this time could be another landmark for cooperation and consolidation of local business. "Everyone wanted to be the leader in the industry before the crisis," said Guo Hui, marketing director, Mingle, a medium-sized enterprise with annual sales of 500 million yuan. "But now survival has become the top priority." But the relative stability has to do with the industry structure here. A main characteristic of Jinjiang is that it has a complete chain of shoe manufacturing business within the city. It is said that one could get all the materials of making a pair of shoes without walking out of the town. Jinjiang has a street with hundreds of stores selling textile, accessories, and plastics used for making shoes. At the end of the street is a big mall for the shoes wholesale business, and only several miles away are large and small shoe-making factories. Before the crisis, over 70 percent of local SMEs make shoes for international brands and then sold the products to overseas markets. But many of them have started to work with other local enterprises as the demands in overseas markets weaken. Some of the SMEs turned to local enterprises with larger scale and higher brand recognition, and started to make products for them. For big companies, outsourcing part of their manufacturing business can help cut costs and improve efficiency. They could be more focused on brand building and developing more distributors, which are key for further expansion. For SMEs, this means that they can stay in business when orders from other countries drop, or even disappear. Most of them want to stay in business even they do not make money, because that is where their home is. "They even use the money they earn before to maintain the operation now," said Chen. "Because if they could survive from the coldest winter, life later would be easier." Now Anta and 361 are at the top tier of the local, or even national shoe-making business, having over 100 other enterprises to make accessories, garments, and the rest of their products for them. Even Mingle, whose scale is much smaller than the first two, has outsourced many of its manufacturing work to the town's smaller enterprises. "We were begging other companies to make shoes for us, but now they have come to us," said Guo from Mingle. Guo sees that as a good trend for the development of local business. "In the future, some of us will only do marketing and design, some focus on making part of the products," he said, "and we will all be professional and competitive."

(For more biz stories, please visit Industries)

|