Switzerland's ABB to boost China presence

By Zhou Siyu (China Daily) Updated: 2012-10-23 09:36Swiss group attracted to nation's human resources potential

The cooling economic expansion and rising labor costs in China have driven a number of foreign manufacturers out of the country, but Swiss engineering group ABB Ltd said it will stay and plans to attract more Chinese talent.

|

|

|

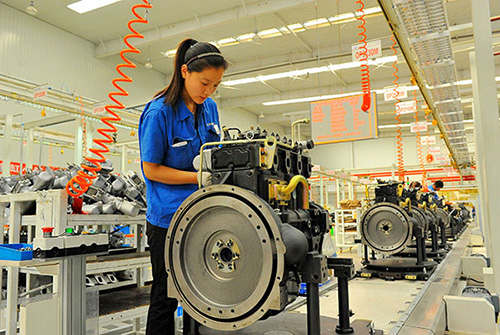

Robots made by ABB Ltd are shown at an exhibition in Shanghai in 2009. The Swiss engineering group said it will set up more than 20 service hubs and centers across China, as part of its $500 million investment plans over the next five years in the country, despite rising costs and cooling economic growth. [Photo/China Daily] |

"We did not come to China to make use of its low labor costs 20 years ago," Claudio Facchin, president of ABB North Asia and China, said in a recent interview. "And despite the economic slowdown in the country in the short term, there is a consolidated view for a strong market in the long run," he said.

But not everyone is as optimistic.

According to a survey recently conducted by the Boston Consulting Group, of 106 senior managers at American manufacturing companies with annual sales revenues exceeding $100 million, more than one-third said they are considering or planning to move their production facilities in China back to the United States.

And 48 percent of companies with annual sales revenues over $1 billion plan to return to the US.

One of the main reasons for the companies' withdrawal is that the manufacturing-cost gap between the US and a dozen low-cost countries, such as China, has narrowed since last year, according to a report by global consulting firm Alix Partners.

It's the first time that the gap has decreased since 2007, the firm said, adding that a number of countries, including Vietnam, Russia and India, now have lower outsourcing costs than China.

A series of other factors, including the appreciation of the Chinese currency and rising raw material costs, are also driving foreign manufacturers away, the firm said.

According to the Boston Consulting Group, Chinese workers' wages have increased 15 to 20 percent on an annual basis in recent years, and this has considerably narrowed the labor-cost gap between China and certain states in the US.

This suggests that China "may have lost some of its competitiveness in some areas of the manufacturing sector", Soren Skou, CEO of Maersk Line - the world's largest container operator in terms of volume - said in a recent interview.

He said he also noticed a clear trend indicating that "Chinese companies are trying to move up the value chain to produce more expensive goods" in sectors including solar energy, automobiles and aviation.

ABB is a good example. The company currently has a full range of business activities in China, including research and development, manufacturing, sales and services, and an extensive sales and service network covering 80 cities, with a total of 18,300 employees in 36 local companies across the country.

"ABB China is now at the fourth stage of its development, which means that it does not only serve the local market, but that its products can also be sold in our other markets across the world," said Facchin.

Apart from China's huge market, the country's human resources are also appealing for the multinational company. One of ABB's most popular products was designed by a research team in China, he said.

While the country may have lost some of its advantages when it comes to low-cost labor, it has "definitely" achieved progress in its R&D capabilities, Facchin added.

In September, ABB said that it plans to set up more than 20 service hubs and centers across China, as part of its $500 million investment plans over the next five years in the country, in order to further boost its competitiveness in the Chinese market.

"We will invest more on people's development, mobility and local leadership development, and hope to attract more talent, adding 25 percent more employees in the next three to five years," Facchin said.

"We look forward to continuing our successful track record in China," he added.

zhousiyu@chinadaily.com.cn

- Experts say bonds offer way ahead for Hong Kong

- China's property loans grow 22.2%

- Phantom screenings: The show mustn't go on!

- Zhejiang Wanfeng acquires US robotics maker Paslin

- Shenyang firm sets up smart machine tool fund

- Chinese banks' loans to small businesses rise 14.5%

- Hainan duty-free sales surpass 19b yuan

- Outstanding loans amount to 98.56t yuan by March, up 14.7%