High-speed trainmakers adding value to human resources

By Zhong Nan and Liu Mingtai (China Daily) Updated: 2016-03-10 08:14

Overcapacity and weak market demand may be affecting many sectors, leading to layoffs, but China's high-speed trainmakers are bucking the trend and intent on adding value to their human resources, even smashing some gender barriers in the process.

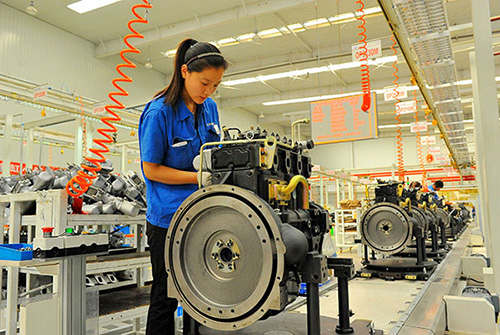

Liu Lili, 35, symbolizes the buoyant state of China's train industry. She is among the rare female electricians in the sector, and contributes to the massive effort that helps make China's bullet trains and other types of modern rolling stock, safe and export-worthy.

Small wonder, global markets are making a beeline for China's reliable trains.

Liu works with CRRC Tangshan Co Ltd, one of the bullet trainmakers of China Railway Rolling Stock Corp, the country's largest train manufacturer. She has been working in the assembly workshop for more than 14 years.

Typically, her job involves connecting various (as in thousands upon thousands of) electric wires to make the trains' onboard systems safe and efficient.

Over the past eight years, Liu and her colleagues have played a key role in building more than 310 high-speed trains, maglev trains and urban rail transit trains with high-quality electrical systems.

"I didn't choose this particular line of work. After I graduated from a local technical college, I had never imagined I would one day work as an electrician on bullet trains. But here I am, in what is generally regarded as a male bastion," said Liu.

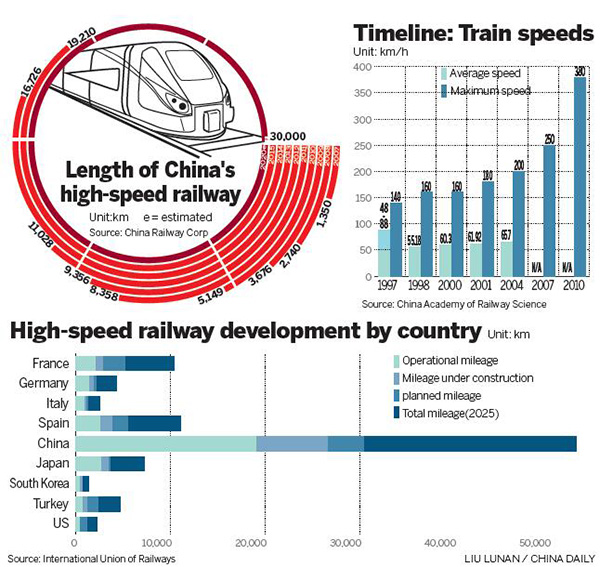

Precision and extreme care mark her trade. China's bullet trains are capable of running at speeds of up to 480 kilometers per hour. Typically, they run in the 300-350 kmph range.

Electricians need to connect more than 100,000 wires in various sizes. There is no margin for error. Even a tiny error could lead to disasters.

Numerous meticulous tests of electrical equipment precede induction of trains into service schedule.

Liu and her workmates were encouraged by their employer to leverage their rich experience and author guidelines for other workers on how to connect wires, use plugs and other electrical fittings during operations.

Thanks to their guidelines, workers now know they need to check a wire's connection or a plug's function at least five times before stamping the okay seal.

Liu and her team introduced the system of inspection labels on which checking duty staff must sign so that procedures followed could be traced back if necessary.

Such rigor has paid high dividends in the form of incident-free operations. Bullet trains manufactured by CRRC Tangshan, Liu's employer, have run for 400 million kilometers so far, and counting.

Convinced quality is paramount, the company has decided to create permanent mechanisms to ensure that. It has sponsored five vocational schools, including engineering and metallurgical machinery colleges in Tangshan in Hebei province, and Shenyang, Liaoning province, to train students who may be keen to qualify as its future workers.

Mechanical engineering courses are taught in English and German. All textbooks, uniforms and tools are shipped from Germany. Trainees can receive job offers after graduation, and have the chance to obtain scholarships to study in both British and German.

"Overcapacity and weak market demand have caused many manufacturers in other industries to either report financial losses or slow growth rate, but they haven't affected trainmakers much, " said Hou Zhigang, chairman of CRRC Tangshan.

- Philips Lighting ramps up R&D spending in China

- Home appliance maker Midea takes smart route to success

- Coal companies shift in direction to battle slump

- Fendi says time is right for expansion of watch sales in China

- Commerce minister: Growth to remain on firm footing

- Experts confident in growth objective

- Experts confident on real estate in China

- Internet Plus plan a real wake-up call for Chinese companies