Siemens pacts power industrial revamp

|

|

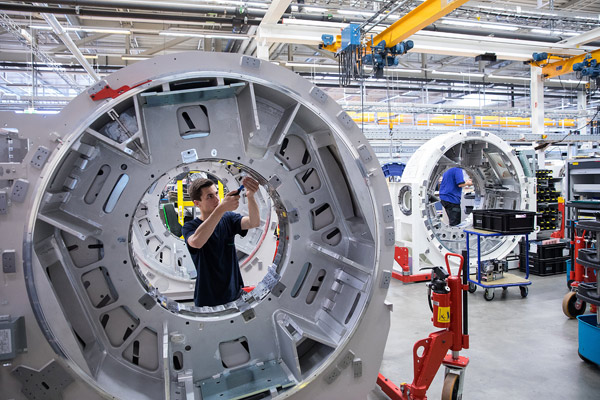

An employee works on the gantry of a Somatom computerized tomography (CT) scanner on the assembly line at the Siemens Healthineers factory in Forchheim, Germany, in July. [Photo/Agencies] |

Siemens AG, the German engineering and electronics giant, plans to build more partnerships with Chinese companies to further develop its intelligent manufacturing business, which, in turn, would support the country's industrial upgrade, said a senior executive.

MindSphere, Siemens' cloud-based open Internet of Things, or IoT, operating system, is designed to help customers evaluate and leverage data to gain new insights and turn data into value.

Siemens has cooperation agreements with China Aerospace Science and Industry Corp, HBIS Group, Baowu Group, Jinyu Biotechnology, Cathay Industrial Biotech, Yunnan Baiyao and Jomoo, to provide consultation services and solutions for digital upgrading, and to help their customers benefit from digital transformation.

It also has a similar agreement with Zhuhai in Guangdong province for a tailor-made intelligent traffic management solution.

It has deployed its Embedded City Sensor Boxes in the Suzhou Industrial Park in Jiangsu province to help reduce traffic congestion and air pollution, optimize infrastructure operation and improve public safety.

Wang Haibin, general manager of the company's Digital Factory Division and executive vice-president of Siemens China, said digitalization today is the most effective way to generate growth, boost competitiveness, and raise quality of life.

It will enable companies to make tremendous progress in many fields in the coming decades and has already transformed all industries, and will continue to do so. "The digitalization of manufacturing has the potential to push productivity to new heights," Wang said.

Siemens and the Hong Kong Science Park also reached an agreement to create Hong Kong's first smart city digital hub in September. Powered by MindSphere, it will tackle the city's challenges through an open, interactive and holistic approach.

Since 2016, Siemens has been increasing its investments in research and development. It planned to spend around 5 billion euros ($5.93 billion) on R&D this year, up by 300 million euros.

Since fiscal 2014, the group's R&D investments have grown by about 25 percent. A major part of these additional funds was earmarked for automation, digitalization, decentralized energy systems and the new ventures unit 'Next47'.

Research intensity, or the ratio of R&D expenditure to revenue, was 5.9 percent in 2016.

"We have discovered an urgent need for what is called supply-side reform, which is in essence restructuring. We are also very familiar with the 13th Five-Year Plan (2016-20), which is also about next-generation manufacturing, and high-end manufacturing in industries such as automotive, aerospace, aviation and others," said Wang.

He Jingtong, a professor of economy at Nankai University in Tianjin, said China's manufacturing industry is experiencing a significant transition from "Made in China" to "Innovated in China".

"We are confident of China's manufacturing upgrade, and more and more Chinese enterprises are leveraging the growth potential arising from digitalization," he said.