Fireworks makers adopt new technology to protect workers

|

|

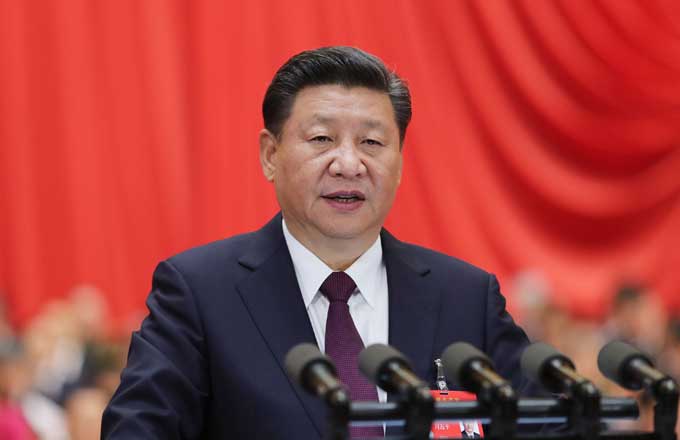

Employees of Liuyang Zhongzhou Fireworks at work on the production line. [Photo by Hou Liqiang/China Daily] |

There are no official statistics about the number of fireworks factories that have failed to renew, or have been refused, licenses, but many have already closed in Liuyang, Hunan province, which is widely regarded as China's fireworks capital because of the high production volume.

Last year, there were about 900 fireworks factories in the city, but the number should fall to 560 by the end of the year, as stipulated by the city's work safety authority. By Oct 18, 215 factories had either closed or had scaled back production.

Overcoming doubts

In 2009, Liuyang Zhongzhou Fireworks was one of the first manufacturers to install an automatic production line, despite doubts among industry insiders and most of the company's 500 shareholders.

The line was installed after three years' of research and development, but it was less efficient than expected, and the company had to spend more than 10 million yuan a year to raise output, said Li Changkai, the president.

"I was the only person among the 500 shareholders to back further investment in the line. The others thought that R & D was a bottomless pit that would never yield returns," he said, adding that he was determined to retain the automatic line because it broke the production process down into individual stages and protected the employees.

"Our workers' safety can only be guaranteed by the use of machines that separate them from the gunpowder," he said.

In 2015, Li saw a light at the end of the tunnel when a third-generation production line was put into operation. The line is capable of producing 2 million boxes of fireworks a year, with an annual production value of 200 million yuan. Moreover, only 11 employees are involved in the process, compared with 300 before. The less contact people have with gunpowder the lower the risk of accidents, the company said.

Liuyang Zhongzhou now operates 10 automatic lines in Liuyang and nearby Liling city, and five more are scheduled to come into operation early next year. However, at 26.8 million yuan per line, few small producers can afford the technology, so Li plans to rent his lines to competitors.

"We will charge companies to rent the lines, and also ask for a percentage of the profits, so we expect to recover the cost of one line in about two years," he said.

"The current line removes the basic safety risks but is not as 'intelligent' as I would wish," he said, noting that the line is unable to produce a wide variety of fireworks. "I'm not satisfied with it, so we will invest more in R& D."

This year, the company has spent 30 percent of its profits on upgrading the line. It has also invested 50 million yuan on construction of a 6,000-square-meter R& D center in Liuyang, and will spend more to bring in fresh talent, he added.

According to the Hunan Work Safety Authority, Liuyang Huaguan Fireworks also put an automatic line into operation this year, after investing 110 million yuan on five years of R& D.

For safety reasons, the line contains just 23 kilograms of gunpowder, spread across 18 separate machines and transport units. No labor is needed if the entire line is operating as planned. The authority said pollution concerns have been addressed by replacing the yellow mud that was traditionally used to block the end of firework tubes, but can contaminate water sources, with a new material that is environmentally friendly and can be recycled to make paper.

Meanwhile, Hunan Kefu Fireworks, in Liling, will soon begin trial operations of an automatic production line.

"There are three main procedures in firecracker production - inserting lead linings, filling the tube with gunpowder, and blocking the end of the tube, which are all dangerous exercises", Pan Jiangping, Kefu's general manager, said, adding that the company has invested 22 million yuan in R & D and the construction of a building to accommodate the line.

"The line will automate these procedures and make production safer. Traditional production techniques mean gunpowder is often exposed to the air, which poses a safety risk. Instead, we will use a closed system to prevent major leaks. Any gunpowder that does leak will quickly be collected to prevent dust from threatening the workers' health."

Li, of Liuyang Zhongzhou Fireworks, has seen many changes during the 20 years he has spent in the industry, and he is adamant that safety is always the main priority.

"Fireworks are for entertainment and should bring people happiness. Accidents were commonplace when they were traditionally made by hand, and resulted in many injuries. I would rather not continue if we can't guarantee our workers' safety," he said.