3-D printing set to become new growth engine

The Weifang High-Tech Industrial Development Zone is speeding up development of 3-D printing technology to make itself a national major production base in the sector.

Founded in 1991, the 110-square-kilometer zone was among China's first batch of State-level high-tech industrial parks. It has become a key production base for a number of high-end sectors, such as automobiles and advanced equipment manufacturing, biomedicine, optoelectronics and electronic information.

Statistics show that last year the zone reported a combined industrial output value of 80.76 billion yuan ($13 billion), of which 54.23 billion yuan was generated from emerging and advanced sectors.

The zone is now home to more than 1,000 high-tech enterprises, including over 50 major companies that each have annual revenue of more than 100 million yuan. Combined revenue from the high-tech enterprises now accounts for more than 67 percent of the zone's total.

Wang Xianling, deputy secretary of the Communist Party of China Weifang committee and secretary of the CPC Weifang High-Tech Development Zone Committee, said the zone attaches great importance to increasing its global competitiveness by developing emerging and advanced sectors, and is now striving to make 3-D printing technology its new growth engine.

To achieve that goal, a 3-D printing technology innovation center, the first of its kind in Shandong province, was established in the zone last year, with a total investment of 100 million yuan. A number of competitive companies have settled in the center. It has formed a complete industrial chain of consumptive material production, equipment control systems and 3-D device production, as well as printing technology service and sales.

One leading company among them is XYZ printing, which hopes to bring its 3-D food printer to market in September for less than 100,000 yuan.

According to Cao Cheng, head of the company's sales and marketing division, XYZ printing is the world's first company with the ability to mass produce 3-D food printers. Founded in 2013, the company is backed by Taiwan's New Kinpo Group, which has more than 15 years experience developing and manufacturing printers, and has built several branches in Japan, the United States and Europe.

XYZ printing's first 3-D printer, da Vinci 1.0, won the 2014 Editors' Choice Award at the Consumer Electronics Show in North America. Its 3-D food printer won the top tech CES 2015 award for its innovative and easy-to-use design.

"Normal 3-D printers are generally used in industrial sectors but the 3-D food printer can bring technology to daily life," said Cao.

"With the 3-D food printer, people who are not good at cooking can make a beautiful cream cake in 10 minutes, while it takes an hour for even an experienced baker to finish one," he said.

Cao said they have shown the 3-D food printer at many expos and it has had a lot of attention, especially from creative food research institutions and educational institutions.

"Students can draw pictures on a computer or iPad then, with the 3-D food printer and Wi-Fi, print food in the shape of the drawing," he said.

Another company settled in the center is the wholly foreign-owned Weifang 3-D Precision Machinery Manufacturing Co Ltd, which specializes in rapid prototyping of 3-D products.

The company provides manufacturing and machinery services for complex metal and non-metal molds, hand models and parts for precision machinery. Its products are widely used by several high-end equipment manufacturing businesses in the zone, such as Weichai Holdings Group, China's leading automobile parts and equipment manufacturer, and Shengrui Transmission, the creator of the groundbreaking 8AT automatic transmission for passenger vehicles.

"Compared with traditional production technology, casting precise molds by using 3-D printers can save about half the cost and shorten 70 percent of production time," said Song Changchun, deputy director of the zone's economic development department.

wangqian2@chinadaily.com.cn

|

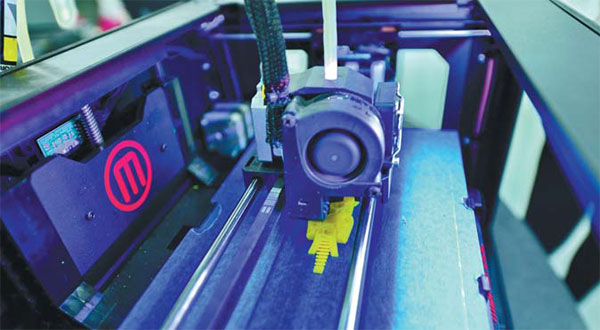

A 3-D printer displayed in the Weifang high-tech zone prints out a mold. Ju Chuanjiang / China Daily |

(China Daily 07/24/2015 page6)