BMW Brilliance opens new Plant Dadong, boosts production capacity

|

A worker wearing an exoskeleton assembles auto parts at BMW's Plant Dadong Northern Extension in Shenyang, Liaoning province. Photos Provided to China Daily |

|

Representatives from BMW Group and BMW Brilliance Automotive attend the launch event for Plant Dadong Northern Extension in Shenyang. |

BMW Group's Chinese venture put its Plant Dadong Northern Extension into operation on Friday in Liaoning province, boosting its total annual production to 450,000 vehicles to fulfill rising demand for premium cars.

The latest extension in Shenyang, Liaoning province, has established itself as a forerunner in the application of Industry 4.0 intelligent technologies in the Chinese auto industry, according to the company.

Thanks to the digitalization of the production process, echoing China's Made in China 2025 strategy, Plant Dadong was recognized as being at the top of its class among the German group's global production sites.

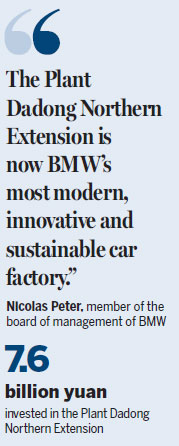

"The Plant Dadong Northern Extension is now BMW's most modern, innovative and sustainable car factory," Nicolas Peter, member of the board of management of BMW, said in an interview.

Using the latest digitized applications enables operators to access data seamlessly for all aspects of production through automated analysis on an internet of things platform.

The identification number of each vehicle is connected to its components, as well as working sequences and machines throughout the production process.

Mobile smart devices such as tablets provide employees with precise information.

To reduce the workload for production employees, innovative exoskeletons can be worn directly on the body.

Like a second skeleton, this structure provides external support for the body and reduces the effort required for physically demanding tasks.

A total of 7.6 billion yuan ($1.1 billion) was invested in the 740,000-square-meter Plant Dadong Northern Extension, equivalent to about 100 soccer pitches.

It took three years to complete construction from the groundbreaking in May 2014.

The premium brand's state-of-the-art plant is currently manufacturing the all-new long-wheelbase BMW 5 Series Sedan, with highly innovative technologies, including advanced lightweight design and extensive use of sensors for driver assistance systems.

"The 5 series is specially designed for Chinese customers, showing our commitment to the Chinese market," said Peter.

BMW Brilliance is offering five localized gasoline vehicles to Chinese customers. Its Plant Tiexi in the west of Shenyang currently manufactures the long-wheelbase version of the BMW X1, the 1 Series Sedan, the 2 Series Active Tourer, and both the long-wheelbase and standard versions of the 3 Series.

Oliver Zipse, member of the board of management of BMW, said Plant Dadong is the result of the BMW production system's comprehensive knowledge and latest technologies.

"The northern extension enables us to add a sixth model to our local line-up: We are preparing for the production of the next generation of the BMW X3 in Dadong," said Zipse.

"We will launch three new models globally in different plants and countries in short succession. Our Chinese plants will be part of all of these global launches," he continued.

The brand's localization strategy is stated as "production follows market demand", which was put into execution at the start of production at Plant Dadong in 2003.

Plant Dadong is the company's first local factory in China. Its second plant- Tiexi - was put into use five years ago. The ribbon on the New Engine Plant was cut last year, ensuring every locally produced car will be fitted with a locally produced engine.

The carmaker has continuously increased its production capacity in line with the enormous growth of the Chinese premium segment.

BMW Brilliance Automotive has invested more than 4.8 billion euros in Shenyang since 2009 and produced a total of 1.6 million cars and 1 million engines in the city. Johann Wieland, president & CEO of BMW Brilliance Automotive, noted that the joint venture is starting a new phase of localization and innovation.

"We are entering the next level of manufacturing technology and capacity, and we are upgrading our research and development center and activities," he said.

The company is planning to invest more in its highly innovative production sites in China this year and in 2018.

Another project it has underway is the remodeling of the southern section of Plant Dadong, aiming for greater flexibility and more potential for growth.

haoyan@chinadaily.com.cn

Highlights

Plant Dadong Northern Extension is built into a full-fledged plant consists of press shop, body shop, paint shop, and assembly.

The new extension erected the benchmark of sustainable production that consumes 32 percent less energy than the earlier section, equivalent to 60 million kw/h per year.

A total of 7.6 billion yuan ($1.1 billion) was invested in the extension. The extension occupies 740,000 sq m of land, about the size of 100 soccer fields. Construction was completed in three years.

Annual productivity of BMW Brilliance with Plant Dadong and Plant Tiexi combined added to 450,000 units per year.

BMW Brilliance has invested almost 4.8 billion euros in Shenyang since 2009.

More than 16,000 associates. A total of 14 new models are offered by BMW to Chinese customers this year.

A total of 191,697 BMW and Mini cars were sold in China in the first four months of this year, up 18.2 percent year-on-year.

(China Daily 05/23/2017 page17)