From red and swollen fingers comes majestic ink decked in black

Apprentice carvers work on ink molds under Xiang Desheng's helpful eye. Provided to CHINA DAILY

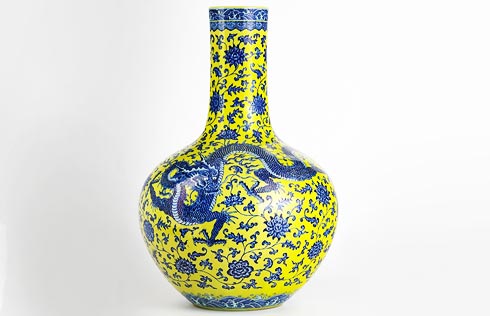

Tiangong Kaiwu, published in 1637, is regarded as one of the first encyclopedias recording handcraft production in China. Its chapter on ink calls the Hui ink stick, made by artisans in Huizhou, now known as Huangshan, in Anhui province, the best of its kind.

In ancient China the ink brush, the ink stick, Xuan paper and the ink stone were regarded as the four treasures of study. For centuries the ink stick produced in Shexian, Huangshan, has been reputed for its quality.

In 1915 the Globe ink stick, made by China's most well-known ink workshop, Hu Kai Wen in Shexian, won the gold award at the Panama-Pacific International Exposition.

"The best ink stick is made of several kinds of precious raw materials, such as musk, gold foil, pearl powder and bear gal," said Xiang Desheng, 54, an ink stick expert in Huangshan.

"Quality ink can ensure calligraphy and paintings never fade if they are properly protected."

Xiang started working in the Hu Kai Wen factory when he was 17. His father also worked in the factory.

"I was lucky to land a stable job, but I did not expect to spend the rest of my life making ink," said Xiang, who was born in a mountain village in Shexian.

Fifteen years after starting to work in the factory he was designated as a master craftsman, and achieving that was anything but easy.

As a novice in Hu Kai Wen, Xiang was assigned to hammer ink dough. Generally, the ink making process includes collecting soot, working with other ingredients, drying, refining, coloring, packaging and designing and carving the mold. In turn each of these steps consists of more than 10 small procedures. Hammering ink dough is a basic procedure during ink making that requires no technical skills but a lot of persistence and strength.

Under the strict supervision of one of his father's workmates, Xiang used a 4-kilogram hammer to pound on ink dough every day, enabling various ingredients to mix well, until they were smooth and even.

The following day his fingers would be red and swollen, and he would be unable to hold anything, he said. In addition, there was always black ink residue under his fingernails.

"No matter how hard I cleaned my hands with soap, they were black."

The work drained him of energy, he said, but he survived with his father's encouragement.

At the same time, Xiang looked for better opportunities in the ink-making department. He wanted to be a real apprentice in the main department. However, the best ink-making masters were unwilling to teach others their skills, so Xiang began to learn the skills surreptitiously.

Each day he would turn up for work before dawn and finish by noon. He would then wander around the workshop seemingly just chatting with his workmates but closely watching how they worked. He memorized the key steps in ink-making and would practice these later, he said.

The artistically talented Xiang began to study and try ink mold carving by himself and made a mold in the shape of a golden pheasant, something the factory accountant saw and liked.

With an ink stick made from Xiang's first mold, the accountant recommended him to the factory manager, who was highly impressed by the mold.

"If we had even 10 talented people like Xiang, that would not be enough," he quotes the manager as saying.

When Xiang was finally relieved of the arduous job of hammering ink and moved to the mold design department his workmates put it down to good fortune, he said, and it was only five years later that they realized how talented and hard-working he was.

He is particularly good at carving delicate and exquisite patterns such as landscapes, buildings, flowers, birds and ships on ink sticks.

In 1992, as the market economy continued to replace the planned economy in China, Xiang, like many people, quit his job in the State-owned factory and set up his own business.

Although he regards Hui ink sticks as pieces of art and not merely writing tools, they need to keep abreast of the times, he said.

When he set up his business he worked in an eight-square-meter room, and 15 years later this had grown into a factory covering 1.65 hectares, the business being called Zimoxuan.

Over the years he produced thousands of innovative ink molds, and his works have won gold awards for arts and crafts in China seven times.

Since 2014 Xiang has been a guest lecturer on traditional ink at the Central Academy of Fine Arts in Beijing.

"The theories he propounds are all systematic and rooted in practice, and his lessons furnish students with the scientific knowledge they need, and they correct misconceptions," said Wu Shoufeng, vice-president of the continuing education school at Central Academy of Fine Arts. "His lectures are extremely popular."

Xiang's son Xiang Song, 27, studied interior decorating, graduating from university in 2013, and looked set for a big-city career. However, his father persuaded him to change course and go into the ink trade.

Now he is one of the youngest masters in this field, and he said he is confident that his trade will be around for many years to come.