From Inner Mongolia to Madagascar

|

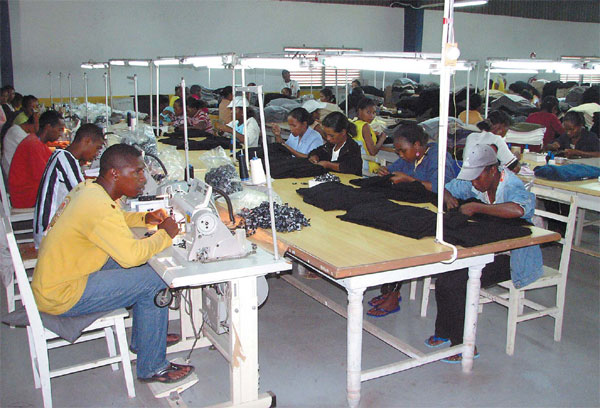

King Deer Cashmere Co Ltd's textile mill in Madagascar employs many local workers and provides them with training in weaving. Provided to China Daily |

A Chinese cashmere manufacturer's decision to set up a mill far from home has paid off

China's reform and opening-up policy, launched at the end of the 1970s, had gathered steam by the 1990s and led to major changes for many Chinese enterprises as well for many who worked for them.

Yao Ruijun, who graduated from college in Baotou in the Inner Mongolia autonomous region and started work for the King Deer Cashmere Co Ltd in 1995, has had some unexpected experiences as the company has grown and changed over the past 19 years.

Yao now speaks two foreign languages, English and French, honed during three years of overseas experience thanks to the company's development.

His first overseas trip was in 2000 to Madagascar, the large island in the Indian Ocean off the southeast coast of the African mainland where the company had set up an overseas mill. He was in charge of the processing business from 2000 to 2003 in the country, where the official languages are French and Malagasy, but English also is spoken.

Yao is now assistant to the company's chairman.

"When we first set up our factory in Madagascar, so many things were unfamiliar and we were really under pressure because of the uncertainty," Yao recalls.

But King Deer has prospered, as has Yao. The company's core product, cashmere, is a textile made from the hair of cashmere goats and other breeds of goat. It is light, soft, strong and has a fine texture.

More than 85 percent of its products are sold to the United States, Japan, South Korea and many European countries. In 1998, when overseas expansion was still a completely new idea for most companies in China, King Deer set up its first overseas mill in Madagascar.

The Madagascar mill now accounts for more than 40 percent of the company's production. King Deer's workforce has grown to more than 10,000, with about 5,000 working in Madagascar. In 1998, the company had about 700 employees.

Exportation policies and foreign exchange policies greatly affected the company's path.

"Before China joined the WTO in 2001, China was limited by various restrictions on exporting its textile products to European countries and the United States, such as high tariff and non-tariff barriers," Yao says. "So it was increasingly important for us to build a manufacture base overseas.

"However, building factories overseas was not at all a common practice for Chinese enterprises at that time, and China did not have a complete set of policies and legislation in this regard," he says. "Therefore, there were many blind areas for us to try, which can be quite risky."

The Madagascar mill is in an industrial park in the national capital, Antananarivo. The mill occupies about 60 hectares of land and is the largest factory in the industrial park.

"All the raw materials are transported from Baotou to the factory in Madagascar. They then are processed into finished clothes and exported to countries all over the world," Yao says.

Madagascar initially attracted the company's attention because of its abundant labor and favorable policies. There were other important factors, says Zheng Haosheng, who became head of the parent company, the King Deer Group, in 2010.

"Weather is an important element. The temperature there is usually around 18C and is sufficiently humid, which means there is no need for air conditioning. Freshwater resources also are a big factor in washing cashmere fabrics," he says.

"What's more important was that Madagascar was in a comparatively stable political situation, compared with other African countries at that time," Zheng says.

The mill was built in a new area, and most of the workers are local people, Yao says.

"Finding a job was quite tough for local workers at the time. We were building our manufacturing base there, and a large number of locals were interested in working in our factory because we offered a better salary," Yao recalls.

He says the local government extended a warm welcome and offered a lot of support as the new factory was built.

"Our business there greatly helped in solving their unemployment issue," Yao says. "And the local young people were willing to work with us because we respect their local habits and customs."

The company also provided local workers with professional training in weaving, with senior workers training new ones.

"Over the past 30 years, with China's reform and opening-up," Zheng says, "our policies and legislation on local enterprises building factories overseas have become more mature. More than 4,000 legislative items in this regard have been revised. These policies help our business run successfully overseas."

King Deer built its second overseas mill in Cambodia in 2009.

"Clothes produced in Madagascar have received lots of acclaim in European countries, especially in Britain," Yao says. "And we hope in the next few years we can recruit more Chinese talent with expertise in French to help with local communications."

zhangyue@chinadaily.com.cn