World's first 3-D printed jet engines created in Australia

|

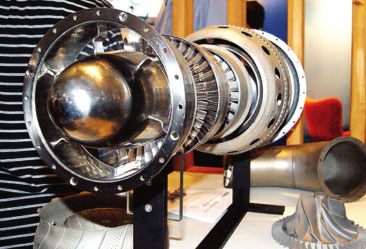

One of the 3-D printed jet engines is displayed at the Australian International Airshow in Melbourne. Lydia Hale / AFP |

Australian researchers say they have created two jet engines using 3-D printing in what is described as a world-first that has attracted interest from leading manufacturers and engineering firms.

The machines demonstrate the potential that 3-D printing has to produce high-quality products, researchers from Mel-bourne's Monash University said on Thursday.

The machines were produced using the template of a gas turbine engine from French aircraft engine maker Safran, which supplies Airbus and Boeing.

"The significance ... is the recognition by major manufacturers and engineering companies like Safran and Airbus that the material you can print using 3-D metal printing is of aircraft quality, and I think that's hugely significant," said Ian Smith, the university's vice-provost.

Invented in the 1980s, 3-D printing uses lasers to "print" objects from metals or plastics based on a digital design.

A recent upsurge in interest has been linked to patents on the original technology expiring, opening the way for competition that will increase quality and reduce prices.

Wu Xinhua, from Monash University, said her team created the machines by pulling apart an old engine and scanning its components. The complex project took a year to complete.

One of the engines is on display at the Australian International Airshow in Melbourne, and the second is in Toulouse at French aerospace company Microturbo.

Jean-Francois Rideau, head of research and technology at Microturbo, said, "Wu and her team at Monash have demonstrated their mastery of additive manufacturing in metal."

Smith said the technology could be used to build prototypes and customized components quickly and cheaply.

The 3-D metals printers could also be used in the biomedical industry to create artificial body parts or equipment.

"You can make parts for the body - replacement joints and hips designed specifically for an individual," Smith said. "A lot of surgeons want to make their own instruments that are customized for them or a particular surgical procedure."

Market researcher Gartner has forecast that worldwide spending on 3-D printing will rise from $1.6 billion this year to about $13.4 billion in 2018.