Rise of robots in China's manufacturing

By Amitendu Palit (China Daily) Updated: 2015-10-14 07:30

|

|

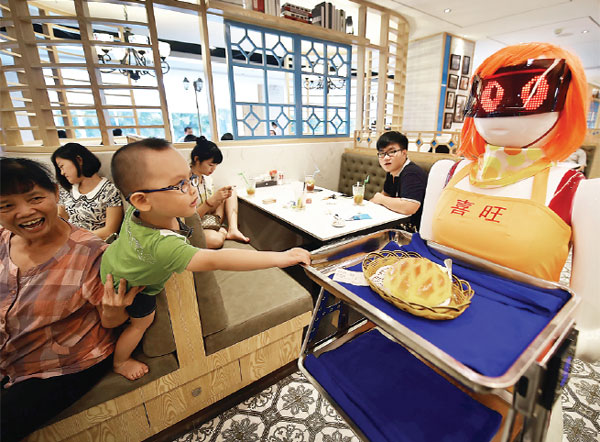

A boy is fascinated by a robotic waitress at a restaurant in Haikou, Hainan province, on Aug 3. [Photo/Xihua] |

China's manufacturing has undergone a significant structural shift, especially in the past five years. Part of this has involved the greater use of industrial robots in some industries. Statistics on the global use of industrial robots provided by the International Federation of Robotics show the operational stock of multipurpose industrial robots in China was 189,358 at the end of 2014.

The stock is expected to increase to 614,200 by the end of 2018, making China the largest user of industrial robots in the world. The extensive use of robots by China will also make Asia a bigger user of robots than Europe and the United States.

Globally, the automotive industry is the largest user of industrial robots, followed by electronics, metals and chemicals. The Chinese automotive industry is the largest in the world. Apart from practically all major global automobile assemblers, such as Volkswagen, Ford, Hyundai, Toyota, Nissan, Daimler, Honda and Jaguar who have assembling operations in China, there are several major domestic automobile manufacturers. These include Shanghai General Motors, Dongfeng and Beijing Auto. The huge expansion of the automobile industry in China partly explains the increasing use of industrial robots in the country. China's abundant processing of hi-tech electronic items has also contributed to the uptake of robots.

Industries such as the automobile and electronics industries are skill-intensive by nature. They require industrial workers who not only possess specialized assembling and processing skills, but workers able to upgrade their skills over time.

Previously, these industries used to spend considerable resources on hiring skilled labor and on skills training. But China's labor market characteristics are changing. It is no longer possible to hire skilled labor at low cost. Industrial skills training has also become expensive. There is also no guarantee that companies will be able to retain workers that are skilled and trained as they are always looking for opportunities to move to higher paying jobs.

Robots are the perfect solution to these problems. They come customized with skills that their industrial employers are looking for. They can be utilized for longer periods of time than human workers without the need to raise wages. They also do not make the typical demands employees make of their employers, such as demands for leave, bonuses, medical benefits and pensions.

But China's heavy use of industrial robots draws attention to their likely effects on the labor market and employment prospects. Given the benefits that robots offer compared with human workers, more industries and businesses, over time, will likely be encouraged to use more robots.

However, this is probably to be limited to more skill-intensive industries with specific requirements for customized assembling such as the automobile industry. Other skill-intensive industries, such as the pharmaceutical industry, which require the greater application of human perceptions and knowledge, are unlikely to introduce robots.

Similarly, industries that are typically more labor-intensive such as the textiles industry are unlikely to rely on robots, except those companies that are involved in the large-scale application of textile designs and batch production. The effect on the labor market and employment, therefore, is not expected to be widespread.

The high use of industrial robots in China comes at a time when Chinese manufacturing is undertaking a decisive shift toward more skilled and technology-intensive production. Whether this will necessarily lead to greater reliance on robots is difficult to say. Some industrial initiatives, such as emphasis on production of carbon-efficient vehicles, might rely more on robots. Much, in this regard, will depend on the changes taking place in the global robotics industry as well.

The high demand from China will increase the cost of using robots. Potential users of robots will obviously assess the benefits of using robots rather than human workers and may decide it is not cost-effective to use robots. But there is little doubt that China will probably be the first among the developing countries and emerging markets to witness intensive application of robots. In this respect, it is likely to catch up with the developed world very soon.

The author is senior research fellow at the Institute of South Asian Studies in the National University of Singapore.

I’ve lived in China for quite a considerable time including my graduate school years, travelled and worked in a few cities and still choose my destination taking into consideration the density of smog or PM2.5 particulate matter in the region.