12 inch 28 nm Etcher passes examination

( Beijing Daily )

The 12 inch 28 nm plasma silicon etcher independently researched and developed by North Microelectronics Co, a subordinate to Beijing Electronics Holding Co, has passed technology certification comprehensively.

China's integrated circuit high-end equipment further accelerates development to reach an international level. The technology difference has been shortened to "three years" from "20 years" in 2003.

Each mobile phone has a small integrated circuit chip. Various patterns on the chip are made by the etcher.

A size of 28 nm is equal to the thickness of one-ten-thousandth of a human hair. The production of the electronic chip used for a mobile phone generally requires 18 types of machines and equipment and over 400 procedures. The etcher is one of the important devices.

The 12 inch 28 nm plasma silicon etcher independently researched and developed by North Microelectronics Co fully passed the process of technology certification for the production line of Semiconductor Manufacturing International Corporation at the end of last year. Customer orders were attained, marking that the localization of China's integrated circuit high-end equipment has made new breakthroughs.

Before North Microelectronics Co made a breakthrough in 28 nm etching techniques, there was only one American company and a Japan company in the world capable of providing mature equipment that can satisfy a 28 nm production line.

For a long time, high-end etching equipment has always faced a bottleneck that restricts the development of the integrated circuit industry in China. Therefore, the release of 28 nm silicon etching equipment by North Microelectronics Co shows that China has realized synchronization with the demands of the main production line in the high-end integrated circuit equipment area for the first time.

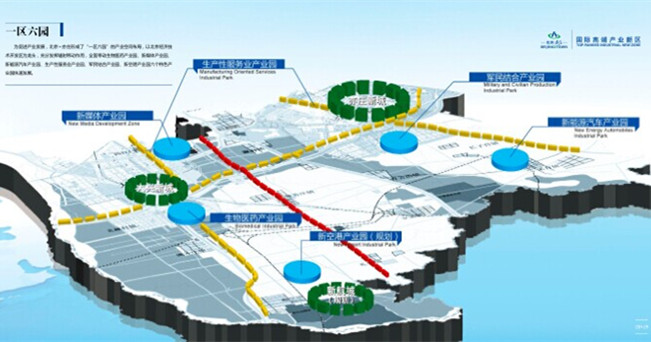

The Area with Six Parks

The Area with Six Parks Global Top 500

Global Top 500