BBAC redefines manufacturing in a digital, flexible and green way

( China Daily )

The all-new Mercedes-Benz A-Class L, the 2 millionth locally built Mercedes-Benz model, went offline from the MFA facility of Beijing Benz Automotive Co Ltd, a joint venture of Daimler and BAIC, this Wednesday.

Superbly crafted, the all-new Mercedes-Benz A-Class L is a representative creature of BBAC, where the manufacturing is being redefined in a digital, flexible and green way.

"The future of manufacturing is here," said Arno van der Merwe, president and CEO of BBAC.

"We are developing a new manufacturing operation aligned with the Mercedes-Benz global production system and underpinned by three key elements: digitization, flexibility and green," he added.

"In this entirely new manufacturing world, everything is connected."

BBAC is already digitalizing its entire value chain from product designs to research and development, logistics, production, quality and financial services. All the steps are digitally synchronized to ensure perfect execution and complete alignment with the customers' needs.

To meet the increasingly personalized needs of customers, the new plant has adopted a flexible production model that combines people, machines and production processes allowing the automaker to produce sedans and SUVs on the same production line, even in both pure electric and traditional combustion engine configuration in the future.

He said intelligent manufacturing is not the end of this particular journey. The company not only wants to provide fascinating and inspirational products, but also to help move the world along toward a greener future.

By extensively applying clean energy technologies, BBAC said it has moved to a production model of low consumption, low emissions and high efficiency.

The latest energy-saving technologies - such as ground source heat pumps, photovoltaic systems and smart lighting systems - have been installed throughout the plant, cutting power consumption by an estimated 14,000 megawatt hours each year.

China has been the largest single market for Mercedes-Benz since 2015.

In the first 10 months of this year, the German automaker delivered more than 560,000 vehicles to Chinese customers, sustaining double-digit growth year-on-year.

Hubertus Troska, board member of Daimler AG responsible for Greater China, said this is an "encouraging result", with the luxury brand's success in the huge market largely attributed to locally produced models.

He added that the vehicles rolling of the BBAC production lines has accounted for more than 70 percent of the total sales of Mercedes-Benz in China.

Back in 2005, the E-Class model rolled of the assembly line as the first Mercedes-Benz model at BBAC. It took the joint venture more than 10 years to locally produce the 1 millionth vehicle in 2016.

Two years later, on Wednesday, BBAC celebrated the rolling of the production line of the 2 millionth vehicle, showcasing the extraordinary growth of the business and its rapid development in the world's largest auto market.

"In just 13 years, BBAC has been able to realize the ideas of 'high speed' and 'high quality' with a world-class plant, five of Mercedes-Benz's best-selling worldwide models, and recognition from 2 million customers. We are setting the standards for manufacturing excellence with a new era of manufacturing language that embraces 'high speed and high quality'", said Chen Wei, senior executive vice-president of BBAC.

China is now also the world's largest market of the C-Class, E-Class, GLC and GLA models, which are the full lineup of the locally produced BBAC portfolio. The all-new A-Class L sedan is the fifth locally produced Mercedes-Benz.

According to the carmaker, the body of the all-new long wheelbase A-Class is manufactured with an automation rate of 99 percent, using more than 650 robots.

BBAC's efforts to promote intelligent and innovative manufacturing have won accolades from local authorities.

The company has been recognized as a Sino-German Intelligent Manufacturing Cooperation Demonstration Pilot Project by the Ministry of Industry and Information Technology. This honor further reinforces BBAC's leadership in premium manufacturing.

Xu Heyi, chairman of Chinese State-owned carmaker BAIC, said: "As the core practitioner of high-end manufacturing and high-end products, BBAC shoulders the important mission of leading Beijing's automotive industry to continue to transform and develop in a high-grade, high-precision and advanced direction.

"In the face of today's technological revolution with many peaks, our industry is constantly improving and opening up. BBAC will continue to adhere to the development path of high-end manufacturing, high-end products, to deepen our integration with emerging industries," Xu added.

In the future, BBAC said it will continue to adopt modern management processes and stringent quality systems, and constantly refine its advanced craftsmanship and manufacturing processes.

caoyingying@chinadaily.com.cn

|

Representatives witness the offline ceremony of BBAC's 2 millionth vehicle and the all-new A-Class L.Photos Provided To China Daily |

(China Daily 11/23/2018 page7)

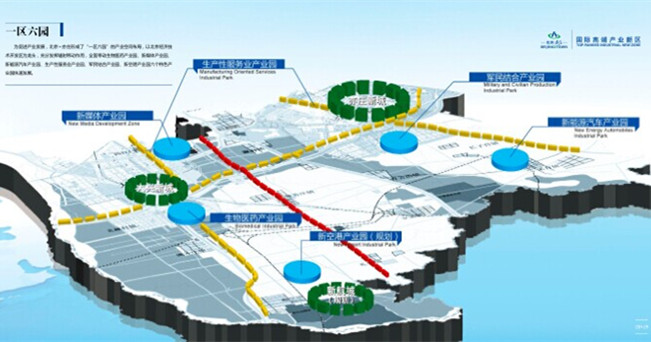

The Area with Six Parks

The Area with Six Parks Global Top 500

Global Top 500