Breaking new ground

Updated: 2012-08-03 08:53

By Meng Jing (China Daily)

|

||||||||

Chinese scientists working on finding green extraction solutions

Despite the prospects of offering abundant natural gas with reduced carbon intensity, the shale gas industry still has a long way to go before it can build a green name for itself.

Much of that comes from the relatively unsafe and dangerous techniques that are currently in vogue for shale gas extraction around the world. Most of the current techniques are based on "fracking", a process by which natural gas is extracted from shale rock by blasting geological formations with a mixture of sand, water and chemicals.

Scientists in China are working on a technology that may not only have the answer to the safety concerns but also offers steady prospects of green energy from shale gas resources.

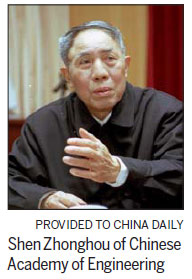

Shen Zhonghou, a member of the Chinese Academy of Engineering, says his team is working on technologies that use supercritical CO2, instead of the present fracking fluid, to extract natural gas from shale deposits.

"CO2 is colorless and harmless, but a major contributor to global warming. By using supercritical CO2 to extract shale gas, China can not only get more natural gas supplies but also cut back its greenhouse gas emission. China also needs to find its own techniques to exploit shale gas due to the unique nature of its geologic formation and water supply situation," says Shen, often regarded as the father of the drill bit in China's oil and gas industry.

The depth of shale gas in the US is 500 to 2,600 meters while in China the reserves are usually found at a depth of more than 3,000 meters. Drilling costs increase considerably because of the increase in depth.

Traditional fracking usually needs more than 10,000 cubic meters of water. In China, with a per capita water resources of 2,100 cu m, or 28 percent of the global average, using water to exploit shale gas seems like an extravagant way to tap the resources, Shen says.

Shen, 84, started to focus his research on supercritical CO2 in late 2003. "We have spent nearly 4 million yuan and several years on research and to build our own equipment for experiments to prove that supercritical CO2 has a desirable drilling performance," says Wang Haizhu, a member of Shen's team.

The test finally succeeded in April. "After hundreds of experiments, we can now safely say that supercritical CO2 can be used for drilling," Wang says.

The top priority for Shen's team is now to put the technology into mining operations.

mengjing@chinadaily.com.cn

(China Daily 08/03/2012 page5)

Relief reaches isolated village

Relief reaches isolated village

Rainfall poses new threats to quake-hit region

Rainfall poses new threats to quake-hit region

Funerals begin for Boston bombing victims

Funerals begin for Boston bombing victims

Quake takeaway from China's Air Force

Quake takeaway from China's Air Force

Obama celebrates young inventors at science fair

Obama celebrates young inventors at science fair

Earth Day marked around the world

Earth Day marked around the world

Volunteer team helping students find sense of normalcy

Volunteer team helping students find sense of normalcy

Ethnic groups quick to join rescue efforts

Ethnic groups quick to join rescue efforts

Most Viewed

Editor's Picks

|

|

|

|

|

|

Today's Top News

Chinese fleet drives out Japan's boats from Diaoyu

Health new priority for quake zone

Inspired by Guan, more Chinese pick up golf

Russia criticizes US reports on human rights

China, ROK criticize visits to shrine

Sino-US shared interests emphasized

China 'aims to share its dream with world'

Chinese president appoints 5 new ambassadors

US Weekly

|

|