US' green energy ambitions losing spark

By LIA ZHU in San Francisco | CHINA DAILY | Updated: 2022-07-05 07:26

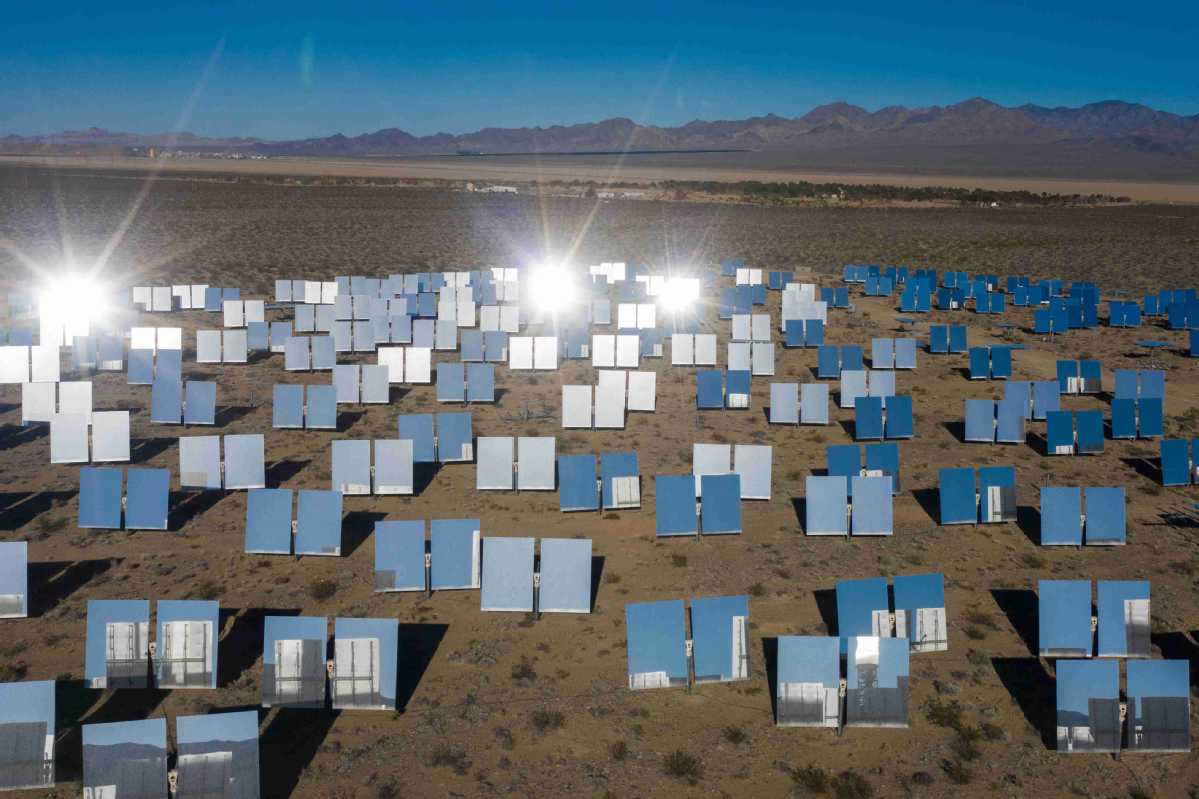

Insufficient capacity

More than 80 percent of the domestic manufacturers say they expected severe or devastating impacts. Two-thirds of the respondents report that at least 70 percent of their solar and storage workforce is at risk and 56 percent of them say at least 70 percent of their current-year solar pipeline is at risk, according to the survey.

The SEIA's data shows that 84 percent of all US module imports come from the four countries affected by the investigation, and there is not sufficient capacity to supply US demand anywhere else in the world except China, which is already subject to tariffs of 40 percent to 275 percent.

If enacted, these new tariffs could reduce solar deployment by up to 16 gigawatts annually, and put 70,000 US solar jobs at risk, according to the national association.

The Auxin petition has also affected energy storage development. Since most energy storage projects are paired with solar, without the solar components, the energy storage components are likely to become uneconomical, according to the SEIA. Putting aside the economics, moving forward would require renegotiation of all project financing agreements.

The renewable energy and storage industries are also grappling with the effects of the "Uyghur Forced Labor Prevention Act" signed into law by US President Joe Biden in December.

The key to the legislation is "rebuttable presumption", which extends the import restrictions to any company that operates in Xinjiang Uygur autonomous region, a mountainous area in Northwest China, unless it can prove its shipments aren't tied to forced labor.

The act took effect on June 21. It has caused confusion for the industry, as "a lot of the industry folks are wrapping their head around what this means", Morris says.

Xinjiang is home to about 50 percent of the world's polysilicon production. Polysilicon is used to make solar wafers, cells and modules, which generate power from light as part of photovoltaic panels.

Despite China's denial of the accusations, US Customs and Border Protection blacklisted solar suppliers in Xinjiang in June last year and two-thirds of the solar modules used in the US became subject to the agency's sweeping detentions from August.

The American Clean Power Association, representing more than 700 companies in the solar industry, has warned that detention and the slow pace of the clearance process have come with a huge economic cost.

The trade group says nearly one-third of the planned utility-grade solar projects set for development in 2021 were delayed or canceled and further unnecessary detentions would translate into billions of dollars in lost economic opportunities and put tens of thousands of people out of work.

There are multiple steps regulators can take to help alleviate some of these disruptions, says Morris, but "the fundamental story is there are a lot of different issues, and each issue has its own discrete set of solutions".

The disruptions to clean-energy projects and utility-scale battery installations are likely to threaten the pace of the US transition from fossil fuels as the Biden administration has set a goal of reaching 100 percent carbon pollution-free electricity by 2035.

In California, a state that already relies heavily on renewable energy, the delayed or potentially canceled solar projects as well as the storage capacity could cause operators to extend the life span of fossil fuel plants, setting the state back in its ambitious goal of relying entirely on zero-emission energy sources for its electricity by 2045.

The Biden administration has announced it would waive tariffs for two years on solar panels from countries affected by the Commerce Department investigation, an attempt to revitalize solar installations.

The White House also announced funding of $3.16 billion to assist with battery shortage development in the country. Officials said the money would help domestic manufacturers make more batteries in the US to address the supply chain issues for components.

Industry experts said bringing a supply chain to the US would take years.

Even siting and permitting a US plant could take a year or more, while construction and production could take an additional one to three years, according to the SEIA report surveying the Auxin petition's impact.

Based on Chinese and Southeast Asian public filings, the association estimates the construction periods for cells and modules at 6-24 months and for polysilicon and wafer at 12-24 months.

Vanessa Witte, a senior energy storage research analyst with Wood Mackenzie, says building the manufacturing and raw-material capacity to meet that demand could take time.

A new mine, for instance, takes around five years to set up, while a battery manufacturing plant would require at least two years, she told Utility Dive, an energy industry news website. "These things just take time to catch up, and that's really been the source of the issue," Witte says.