Nuclear fusion dream moves closer to reality

By Barry He | China Daily Global | Updated: 2023-01-11 10:39

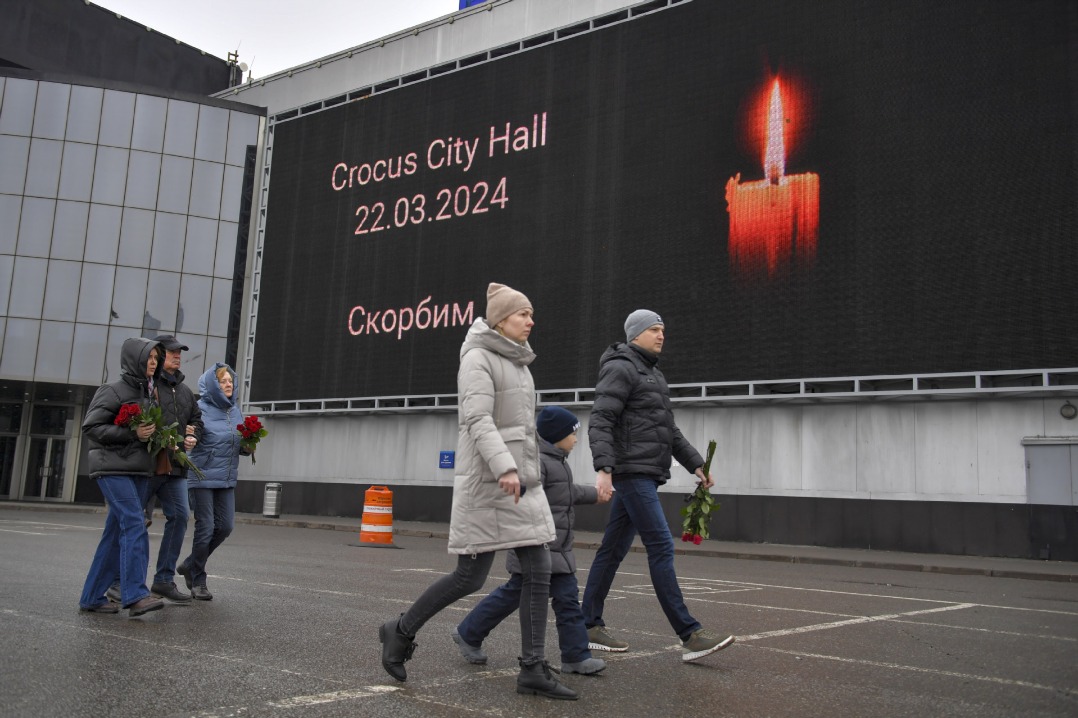

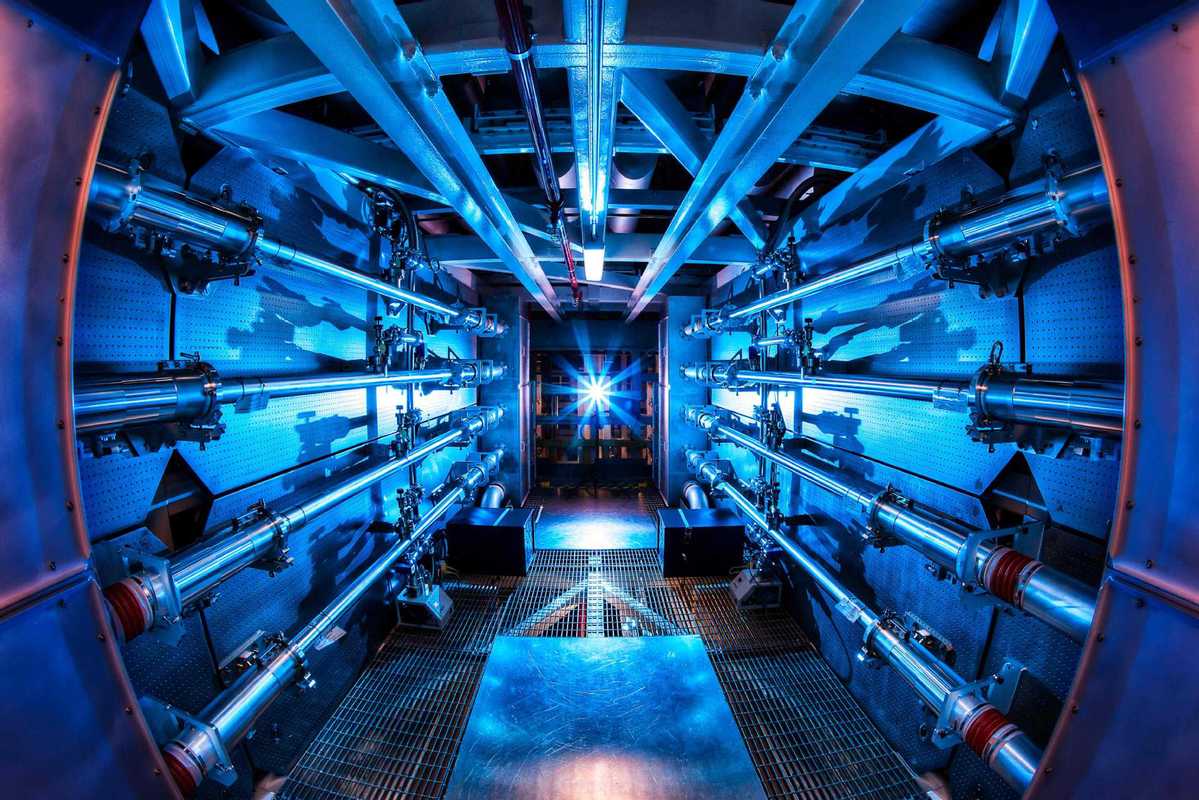

The breakthrough in nuclear fusion toward the end of last year has brought fresh excitement to the international science community. The prospect of near limitless amounts of clean energy has come closer to reality, as engineers from the Lawrence Livermore National Laboratory managed for the first time to produce more energy than was used to create it. This net gain of energy, however, is far from the whole story.

Many factors must be accounted for before fusion energy becomes economically viable. In fact, while technically possible, our first fusion power plant may potentially still be many years away due to current engineering limitations. To speed this process along many issues must be addressed, even if the basic principle has already been achieved.

The materials required to create fusion reactors are far from ordinary. Components of reactors must be able to perform under extreme conditions, where temperatures will fluctuate more widely than even the surface of the sun. New generations of metal alloys, which can withstand high melting temperatures are in the works, with metals such as tantalum and niobium currently being experimented with. For fusion to be viable as an energy source, which could combat our current climate crisis, the cost of these materials must become economically viable. To make things even more difficult, these materials must also fit the profile of being unreactive to radiation, being stable to the point where problematic reactions from radiation do not occur.

Cooling super-hot plasma within reactors cheaply also remains a challenge, as if the gas breaks free from the magnetic field it can risk causing damage to the reactor internally, and destroy even the hardiest of metal alloy compounds. Novel techniques such as "inside out" cooling involving diamonds are currently being researched, however, to combat this thorn in the side of nuclear engineers.

Thin-walled diamond shell pellets containing boron are injected into the plasma. Fired at a high speed of 725 kilometers an hour, they can deposit this boron dust deep into the plasma where the diamond shells then disintegrate, delivering the payload deep where they are most effective. This efficiently radiates away excess heat from the plasma and reduces stress within the reactor. The materials required to produce diamond shell pellets, filled with a gas that can be injected into the reactor at over half the speed of sound, will not be a cheap process. Ensuring that the process is accessible enough to countries where economies of scale can take effect will take time, in order to make the process of fusion energy reliable.

There is a running joke among engineers and scientists in the nuclear fusion industry that the prospect of clean fusion energy is always just 30 years away. The cusp of achieving the holy grail of energy production is one that will be overcome through sheer tenacity and investment into novel materials and engineering solutions, as well as finding ways to make the process affordable. Other technologies such as hydrogen fuel cells are in a similar boat, where modern technology is on the cusp of making them a mainstream accessible alternative to fossil fuels. While the world waits, scientists are working around the clock to make these dreams a reality.