Urgent need for self-branded products

By Hong Liang (China Daily) Updated: 2012-12-17 13:16Many economists, analysts and commentators in China have dismissed the so-called insourcing by Apple and some other multinational companies as nothing but isolated cases that pose no real and immediate threat to China's industrial might.

They contend that even allowing for further increases in workers' wages and an uptake in inflation, the cost of manufacturing in China will remain significantly lower than the cost of manufacturing in developed countries. For that reason, they believe that any talk about the demise of globalization is premature.

Tim Cook, Apple's chief executive officer, is known as an expert in outsourcing. Cook joined Apple in 1998, as senior vice-president for worldwide operations, and he is credited with closing all Apple's factories and establishing an efficient supply chain by globally outsourcing the manufacturing of the company's products. However, he now deems that it makes economic sense to have some of the company's products manufactured in the United States. People should take note.

In fact, Apple isn't the first multinational company to find that manufacturing in developed countries can be just as cost efficient as making them in China or other relatively lower-cost manufacturing bases. Dutch consumer electronics giant Philips has built a factory in Drachten, the Netherlands, where 128 robots are doing the same work as hundreds of young workers do in a sister factory in Zhuhai in China's Guangdong province.

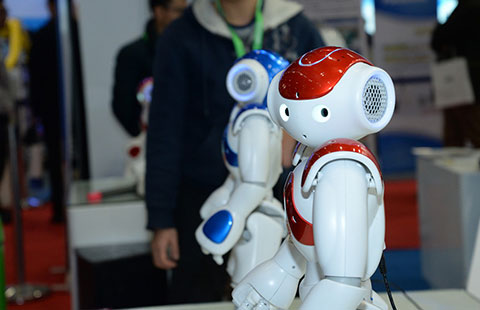

Robots are already widely deployed in automobile factories, aircraft assembly plants and other heavy-industry facilities. But only recently have they been successfully built and programmed to do more delicate and precise assembly jobs that are commonly done by young human workers.

Many large-scale Chinese factories in the industrial heartland of the Yangtze River Delta region have already begun the process of robotizing to improve efficiency and reduce the wastage arising from human error. Some economists predict that China's demand for robots will outstrip that of any other country in coming years.

But the question is: What's the advantage of robotizing a Chinese factory doing mainly original equipment manufacturing on contract to foreign buyers? The one great advantage these manufacturers enjoy is that they can build goods to the specifications of their customers cheaper than their competitors next door, or in some other emerging markets or development economies.

Putting more robots on the assembly lines is not going to help these factories win OEM orders when the orders are being directed to those equally cost-effective robotized factories nearer the major markets in developed countries. It is estimated that more than 50 percent of China's total exports consist of goods manufactured under contract to foreign buyers.

Economic planners have been calling for the speeding up of the restructuring of the Chinese industrial sector, focusing on the development of self-branded products for the domestic and overseas markets. Such calls appear to have acquired a new sense of urgency as the advancement in robotic technology is threatening to upset the global formula of the division of labor.

The more forward-thinking entrepreneurs in Wenzhou are known to have acquired long-established garment and shoe factories in Italy and some other European countries primarily for their brand names and design expertise. This apparently has proven to be an effective shortcut.

The real proof, no doubt, will eventually lie in the determination of the management of many larger manufacturing enterprises, including those owned by the State or related to local governments, to shake off their complacency or break out of their monopolistic cocoon to compete in the global marketplace with products of their own design and specification.

- Carnival of creation, imagination uder way in Shanghai

- Outstanding loans to small businesses up 15.5%

- China's property loans see fast growth

- Samsung sues Huawei in China for patent infringements

- Reform only way forward for China's economy

- G20 members urged to take broad-based policies to support global growth

- Squeezed in sedan, Chinese families with more kids look to MPV

- China cuts retail fuel prices