Wood fans maintains an ancient tradition

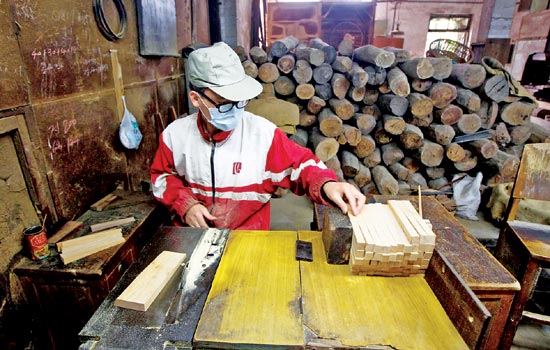

By Xie Yu in Suzhou, Jiangsu (China Daily) Updated: 2012-07-30 10:01If you have never seen a fan-making workshop, you would be surprised at what a demanding craft it is.

A middle-aged woman is using a bamboo bow to carve flowers and patterns on a sandalwood folding fan. The iron wire bowstring pierces the thin wood periodically. It takes one-and-a-half months to make just three quality fans.

"It will be much easier and faster to carve using a machine but the patterns wouldn't be so fine and smooth," said Sun Yaowen, deputy general manager of Suzhou Sandalwood Fan Co.

With air conditioners and electric fans so popular today, they have brought a crisis to the centuries-old craft of fan making.

Sun and his colleagues are struggling hard to survive.

"There were about 680 workers at my company before 2004. Now only 35 are left," Sun said.

"When we were at our peak during the 1980s and 1990s, our factory used to make 10,000 fans a day. Can you imagine that?" he said.

Demand from Japanese and Chinese markets was very strong at that time. One machine-made sandalwood fan sold for 100 yuan ($15.87) for export, equal to the price of an electric fan.

The old workshops are now in a spacious plant located in the quiet old city of Suzhou in East China's Jiangsu province. It is almost empty bar the few surviving employees toiling away. "We do not need such a large output now," Sun said.

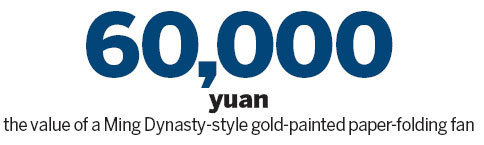

They see their way forward by offering exquisitely crafted handmade fans. As the place of origin of China's southern-style fans, the ones from Suzhou are elegant in appearance but time-consuming to make. Learning to carve the wood, for example, takes at least three years. However, the finest fans can only be fashioned by masters with at least 10 years of experience. Each one costs 35,000 yuan.

"When market demand shrank, we tried to make the business work by targeting high-end customers," Sun said, noting that although home use of fans is decreasing, more people are buying them as souvenirs and gifts, treating them as objets d'art.

Last year, they had revenues of 7.5 million yuan, which is not bad for a company with only 35 employees.

But a new crisis has struck with the price of sandalwood rocketing in the Chinese market. In 2004, sandalwood sold for 500,000 yuan a ton in the timber market. Now real sandalwood is rare and it costs 12 million yuan a ton, Sun said.

The reason is that India, the source of the fragrant wood, has listed the tree as endangered and strictly limited sales.

Sun said they are now using other kinds of wood to replace sandalwood for common products but still accept a few tailor-made orders, by using existing stocks of sandalwood. The price is still very high, he noted.

Sun and his colleagues at Suzhou Sandalwood Fan Co have managed to survive so far and are trying hard to make progress in an era in which fans are no longer one of life's necessities.

- China's express deliveries booming in 2015

- Shares slump to a halt on the first trading day of new year

- Confinement center provides high-end service to new moms

- Caixin China manufacturing PMI edges down in December

- Experts turn attention to technological progress

- Market dives as investors dump shares to avoid volatility

- China's high-tech exports beat Japan and South Korea

- PwC takes China's positives into account