Cotton farmers reap harvest

|

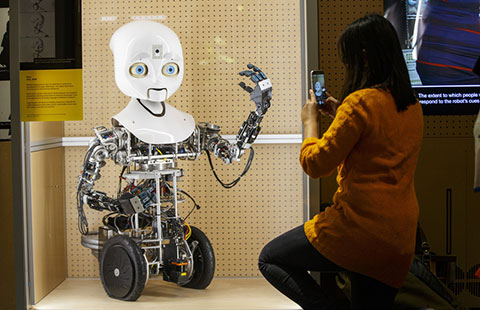

Workers at China-Tanzania Modern Agricultural Industrial Park. The park exports approximately 80,000 tons of cotton yarn each year. [Photo/ China Daily] |

Chinese firm sows seeds of success with Tanzania park

Tanzania's cotton industry reaped in $81.52 million in exports last year. It employs nearly 16 million people in a nation of 45 million. It provides around 13 percent of the country's agricultural exports, second only to coffee.

Still, the country's cotton farmers are suffering because of a system with no safety nets.

A private entrepreneur from Yancheng, Jiangsu province, hopes to change that.

The Dahong Group expects to complete the construction of the China-Tanzania Modern Agricultural Industrial Park by early 2014. The park, which broke ground in June, will help the African country improve its textile manufacturing sector and provide a blueprint for private textile companies in Jiangsu province that are looking to expand overseas.

"It's definitely a win-win solution," says Wang Shuchen, general manager of Tanzania Dahong Cotton Products Ltd, a subsidiary of Dahong Group based in Shinyanga, northern Tanzania, one of the country's major cotton production regions.

The park currently provides training for 3,000 Tanzanian farmers each year, and exports approximately 80,000 tons of cotton yarn overseas, including China.

Despite the African country being a major source of cotton, nearly 400,000 farmers have seen little improvement in their lives. Many live in poverty and do not have the means to refine the cotton they produce. Around 70 percent of Tanzanian-produced cotton is raw. Many are also cheated out of fair prices by middlemen, who buy the cotton and sell it to ginneries for refinement.

Tanzania is listed by the United Nations as one of the least developed countries in terms of per capita income, despite sufficient soil resources, a long planting history and a large farming population.

Last year, the Tanzanian Cotton Board, a government body, looked to numerous countries hoping to stimulate growth in the industry and improve the domestic economy. Seeing a good opportunity, the Dahong Group came up with an idea for an industrial park.

"We can import our knowledge and technologies to Tanzania, and also make our products more competitive in the world market," Wang says.

The first phase of the 1,000-acre industrial park was recently completed. After phase two's construction is completed in 2014, experts and farmers sent by the Dahong Group will take up residence in Tanzania to train the African farmers.

It took $65 million to build the first phase, which includes two cotton processing factories, a textile factory, a honey-refining factory, a packing factory, an oil pressing plant and an agricultural demonstration school.

There are, however, five major problems with Tanzania cotton industry, Wang says.

In terms of cotton planting, the seed varieties currently used in Tanzania have been used for many decades. Wang says they are a source of the country's poor productivity and the crop's poor quality. Many of the varieties, he says, take longer time to grow and because farmers don't have the financial means to manage their fields with fertilizer or build farm infrastructure such as irrigation, harvests of the cotton have suffered over time.

The country also lacks of modern cotton farming equipment. Local farmers often produce a high quantity of cotton without using the necessary equipment, leading to a cotton yarn that is poor in quality. In many cases, the unrefined cotton and lint fall to the ground without any measure to keep it from getting wet. In the rainy seasons, cotton is often destroyed by the rain.

Wang also points out that there is no grading system for cotton to rate their various qualities. All cotton is sold at the same price. He says local farmers lack modern growing methods and desperately need government subsidies to help them.

"Those mistakes are very basic and local farmers need systematic knowledge on cotton planting. In our demonstration school, we will teach them with our textbooks in Kiswahili to change those wrong ideas."

The Dahong Group will run a series of workshops in demonstration field to teach advanced skills and also recruit locally educated people to learn to use their modern equipment shipped from China.

The Tanzanian government has thus far offered strong support to the park's development. Ten villages nearby have been organized by the local government to cooperate with the park. In return, the Chinese company is willing to pay a higher price for the cotton at the market. About 300 job opportunities were available when the textile factory was operational in June.

"The friendship between China and Tanzania creates a good investment environment. Our program, which benefits my company's interest as well as local farmers', can be a strong support to the friendship of the two countries in the future," Wang says.

zhaoyanrong@chinadaily.com.cn

- Local harvests give China record cotton reserves

- Cotton gains as global stockpiles head higher

- High prices, weak demand weigh on cotton industry

- Xinjiang sets world record for cotton production

- Farmers join hands to reap cotton harvest

- Global cotton glut to triple Chinese inventories

- China to sell cotton stockpiles next week

- Declining cotton demand leaves rising inventories