Jiangsu companies take the lead in smart manufacturing

To highlight Jiangsu’s substantial progress in smart manufacturing, a media delegation toured the province from Nov 9 to 12, in search of the latest innovations in the industry.

During a tour of Suzhou’s Wujiang district on Nov 12, the delegation visited Guowang High-tech, a subsidiary of the Hongsheng Group, which specializes in the production of thread for clothing manufacture.

Inside the production base, efficiencies have been achieved through the use of automation, speeding up the manufacture of the thread and reducing the man hours required to do it.

A spokesperson said that before the automation, 10 workers were required on each production line, but now only four are needed. Spindles of fiber are spun at an amazing speed and high quality too. While a standard thread will contain 288 super-thin strands, those produced at Guowang High-tech contain 300. After the spindles are spun they are then transported along a conveyor system in order to be packed, stacked, and shipped.

|

|

Spinning cakes on the assembly line. [Photo by Miao Jiayu/chinadaily.com.cn] |

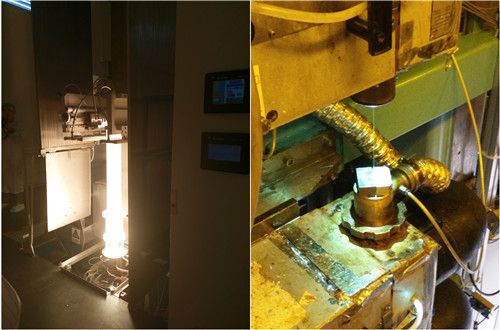

The automated production line, purchased from Italy, is constantly being improved upon, with the tiniest details making a difference on the balance sheet. For example, labeling which was previously carried out by workers is now processed via laser printer, saving the company millions of yuan each year.

|

|

A laser labeling device introduced to the production line at Guowang high-tech. [Photo by Miao Jiayu/chinadaily.com.cn] |

Thanks to the savings made of the production floor, the company was able to increase its investment in technological R&D to 15 percent of its total spending, employing 4,000 staff.

A company representative said that they now encourage departments to release their innovations on a regular basis, rewarding those that prove successful.

Next stop on the media tour was Hengtong Group, which produces optical fibers for data and information transmission.

During the visit to the seven-floor factory, the media representatives were impressed by just how thin the company is able to produce an optical fiber, down to 125μm, which is thinner than human hair.

|

|

A fiber perform is drawn into a thin optical fiber. [Photo by Miao Jiayu/chinadaily.com.cn] |

According to a company spokesman, the quality of the fiber is the reason they can manufacture it so thinly. Due to the fact that fiber optic technology is an often guarded secret, Hengtong had to rely on its own research and innovation. Its success has filled the technological gap in the domestic market and built its own brand internationally.

Hengtong has over 30 overseas subsidiaries and its products have reached more than 120 countries and regions. Besides civil projects, it also provided optical fiber for the Beijing National Stadium and the Chinese pavilion at the Shanghai expo.

The two privately-owned companies are blazing a trail in smart manufacturing across Jiangsu, and truly represent the brand image of “Made in China 2025”.

Edited by Owen Fishwick