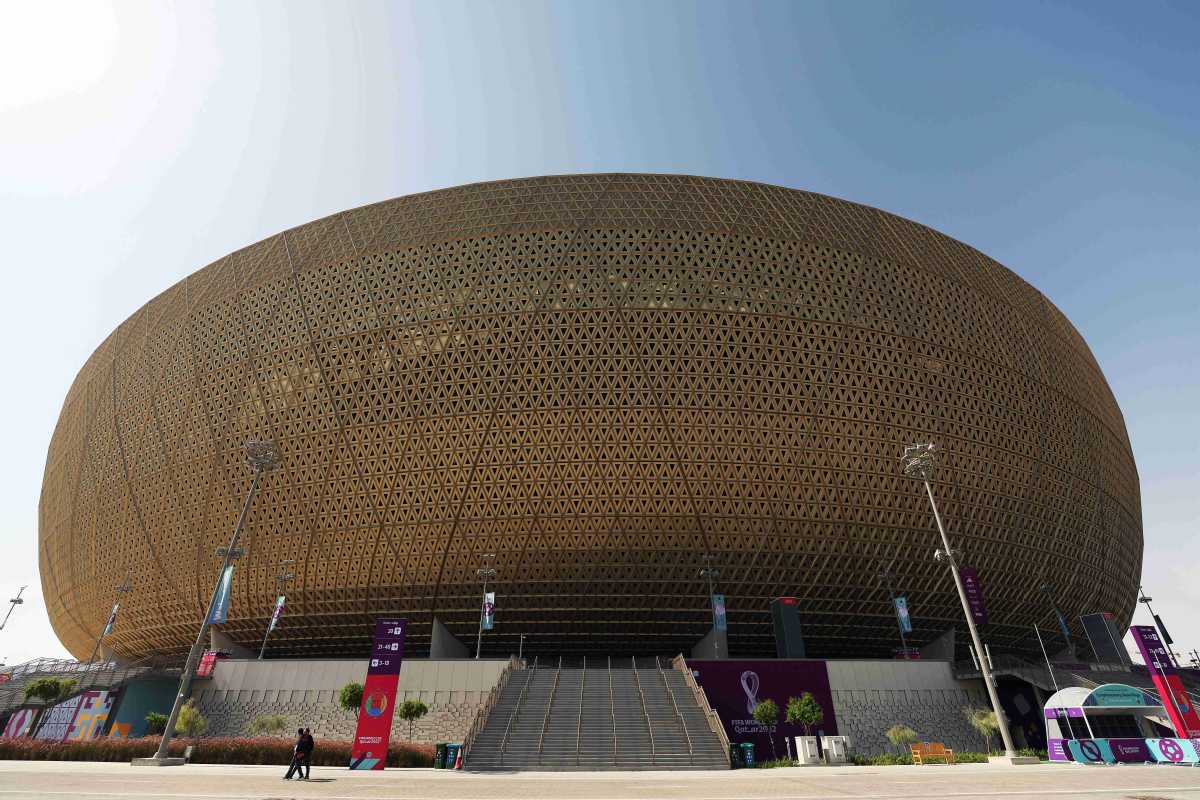

World Cup venue, site of final match, built by China Railway Construction

By ZHU WENQIAN | China Daily | Updated: 2022-11-22 09:14

Lusail Stadium, Qatar's biggest sporting venue, will host this year's FIFA World Cup final, marking the first time a Chinese company served as a main contractor to build a FIFA World Cup pitch.

The golden bowl-shaped 80,000-seat capacity venue was built by China Railway Construction Corp Ltd. Located in Lusail, some 20 kilometers north of Qatar's capital Doha, the stadium was completed in 2020 after 40 months of construction. During this year's World Cup, the venue will stage 10 matches, the most for any stadium during this tournament.

With high temperatures and humidity in Qatar, coupled with exacting building standards, construction of the stadium has not been easy. State-owned CRCC said it has organized teams of more than 7,000 workers from China and abroad, and given full play to its resource integration advantages.

CRCC carried out practical cooperation with more than 20 third-party enterprises, such as UK company AFL and multinational firm Aurecon. CRCC has formed strategic partnerships with these enterprises in the areas of design, steel structures, membrane materials and electromechanical equipment among others, it said.

"The successful building of the stadium has been another important milestone in the overseas development path of CRCC," said Zhuo Lei, president of China Railway Construction Corp (International).

"Qatar has been an important part of the Belt and Road Initiative. The project has shown an important referential significance for China to continuously promote the BRI, and further expand cooperation with countries and regions involved in the initiative," Zhuo said.

The venue is one of the most environmentally friendly stadiums globally. Sustainable building practices were applied throughout the construction of the facility. The construction process has saved about 40 percent of freshwater consumption compared with building a traditional stadium.

For instance, workers collected, recycled and reused rainwater, and they also used desalinated seawater, and recycled water was used to irrigate plants around the stadium.

The project also utilized related technologies to simulate temperature, humidity and air velocity in the stadium, and comprehensively considered the locations of large cameras and media platforms to reasonably arrange seats and make audiences feel comfortable. The building of the stadium also ensures compliance with the requirements of FIFA, said Hameed Otaibi, a Jordanian engineer who participated in equipment installation at the stadium.

Meanwhile, Leonidas Tzevelekas, a Greek engineer who has participated in construction of the stadium for the entire process, said that by relying on advanced digital technologies adopted by Chinese enterprises, he and his colleagues have been able to control construction accuracy down to the millimeter level.

"The project will help speed up the pace of Chinese enterprises and products going global. It will become another golden name card of Chinese enterprises that have successfully operated abroad, and lay a solid foundation for Chinese enterprises to further develop in overseas markets," Zhuo said.