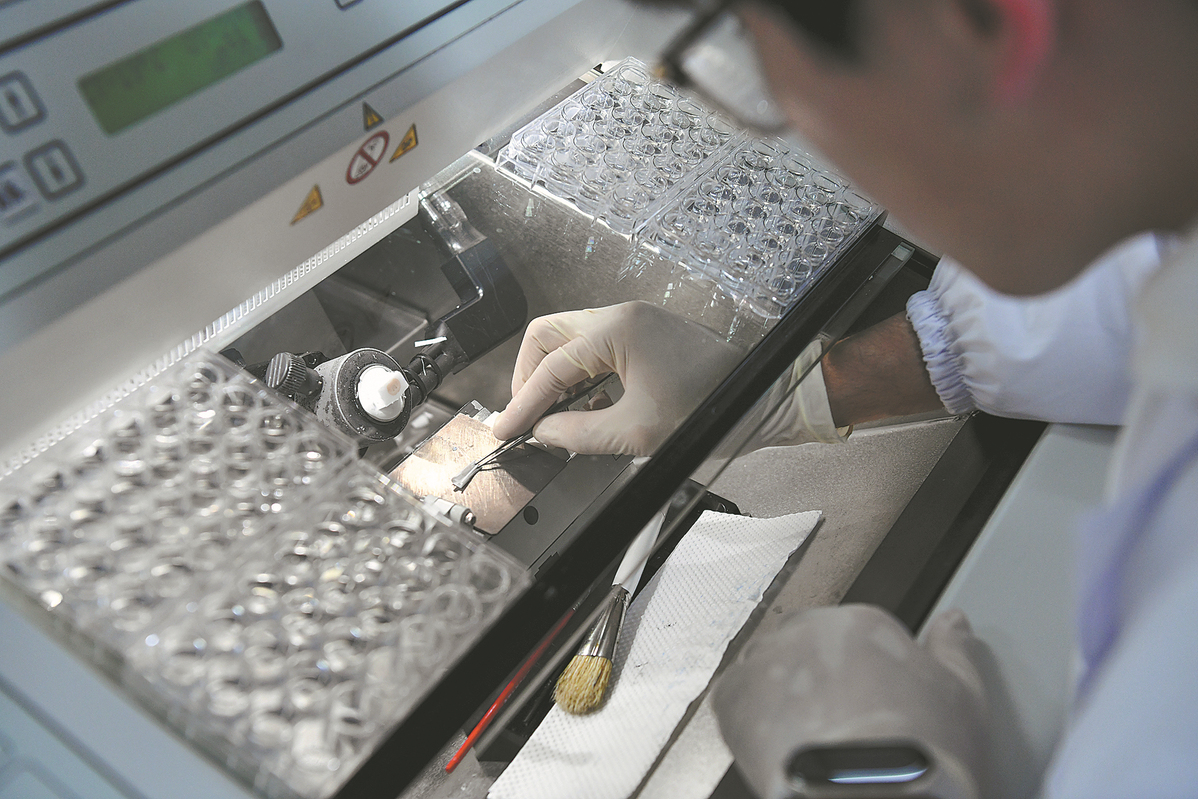

Rise of a new manufacturing powerhouse

GBA sets sights on becoming hub for next-generation industrial revolution

By SHI XIAOFENG and ALICE ZHU in Hong Kong | China Daily | Updated: 2025-01-14 08:59

Legacy continues

Li Chen, an associate professor at the Centre for China Studies of the Chinese University of Hong Kong, views the success of the GBA as a natural outcome of its inherent strengths.

"The GBA has a large cluster of world-leading universities and research institutes. And we have a very good innovative ecosystem," he explained.

In the meantime, he highlighted the GBA's strong cultural legacy — an enduring willingness to embrace risk and pursue unconventional business avenues.

"There's a strong continuity in terms of the entrepreneurship culture in this sphere," he said.

Shenzhen and Zhuhai in Guangdong province were among China's first special economic zones established during the country's reform and opening-up in the late 1970s. Despite their transformative changes over the past decades, the spirit of urban pioneering persists.

Take the example of Felix Choi Chun-kit, a Hong Kong industrialist and CEO of Hongrita Holdings. His mold production company, founded in 1988 in Hong Kong, has witnessed the GBA's seismic shift.

In 1993, Choi moved his operations to Shenzhen, then a hub for labor-intensive industries.

He recalled the early challenges posed by Shenzhen's underdeveloped industrial supporting facilities.

"Even for something as simple as a screw, we had to source it from Hong Kong and bring it to Shenzhen," he said.

Today, the GBA's industrial capabilities are all-encompassing. "We can find all the components that we need locally with very competitive quality and price," he said.

Choi has since inaugurated a digital, intelligent workshop in his Zhongshan facility, where the production line operates autonomously, with high-end robots gliding along preset routes.

From 2018 to 2022, Hongrita's average annual production value per employee increased by about 37 percent, reaching an annual output value of 600 million yuan ($86 million).

With manufacturing cycles averaging 45 seconds, every second saved translates into an additional 4 million yuan in benefits.

The recent opening of the Shenzhen-Zhongshan Link, which cut travel time between the two cities from two hours to just 30 minutes, has further streamlined operations.

Technological advancements and process optimization have reinforced the confidence of manufacturers like Choi. "In the end, precision molds will be labeled 'Made in GBA'," he said.

Looking ahead, Choi aims to transform Hongrita into one of the "lighthouse factories", a term coined by the World Economic Forum to designate benchmark manufacturing sites that integrate cutting-edge technologies with efficient and sustainable practices.

In 2023, the forum's "lighthouse factories" list included 62 Chinese factories, with eight located within the GBA.