Relying on the advantages of its talents and technology, Guizhou Aerospace Electrical Appliance Co, a Guiyang-based electronic components manufacturer, recently developed an automatic visual inspection device, making inroads into intelligent manufacturing.

The device uses advanced vision detection technology to carry out real-time data acquisition. It has become the most productive piece of equipment in the company, eliminating the need for 28 procedures and 38 operators and creating over 2 million yuan ($297,580) in economic benefits.

|

|

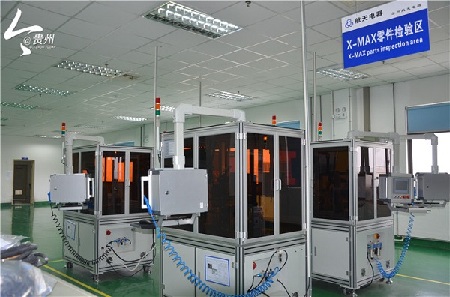

The X-MAX intelligent production line of Guizhou Aerospace Electrical Appliance Co. [Photo/todayguizhou.com] |

The device can inspect three products per second, meaning it can produce 130,000 products in a 12-hour period. It also has a first pass yield of over 95 percent, making it far more effective than naked eye detection.

In addition to electronic components, the detection technology will also be widely used in packaging machines, screw inspections, and fully-automatic assembly machines in the future.

|

| Each device can inspect three products per second. [Photo/todayguizhou.com] |

During the research and development of the automatic visual inspection device, the company mastered several key technologies related to optical inspection, and established standardized scheme designs for hardware and software to ensure the successful production of universal detection devices.

Shi Jincheng, assistant chief engineer of the company, said that intelligent manufacturing has become the main form of industrial production, while visual inspection is essential to the success of intelligent manufacturing.

In the future, the company will strive to integrate visual inspection technology with artificial intelligence, deep learning, and big data in order to make industrial production even more efficient.

|

|

Guizhou Aerospace Electrical Appliance Co is a Guiyang-based electronic components manufacturer. [Photo/todayguizhou.com] |